Nano-Waterproofing Technology: The Key to Elevating Vietnamese Footwear Value

In the modern fashion era, the industry is shifting strongly toward Functional Fashion. Vietnamese footwear brands have a golden opportunity to break through by integrating advanced technology. The decisive factor for this transformation is the application of Nano-Waterproofing Technology.

1. The Chemical Science Behind the Nano Revolution

Nano technology is far more than just a surface coating. At JM, we dive deep into molecular structures to create the most durable protective barriers.

The Invisible Shield Mechanism

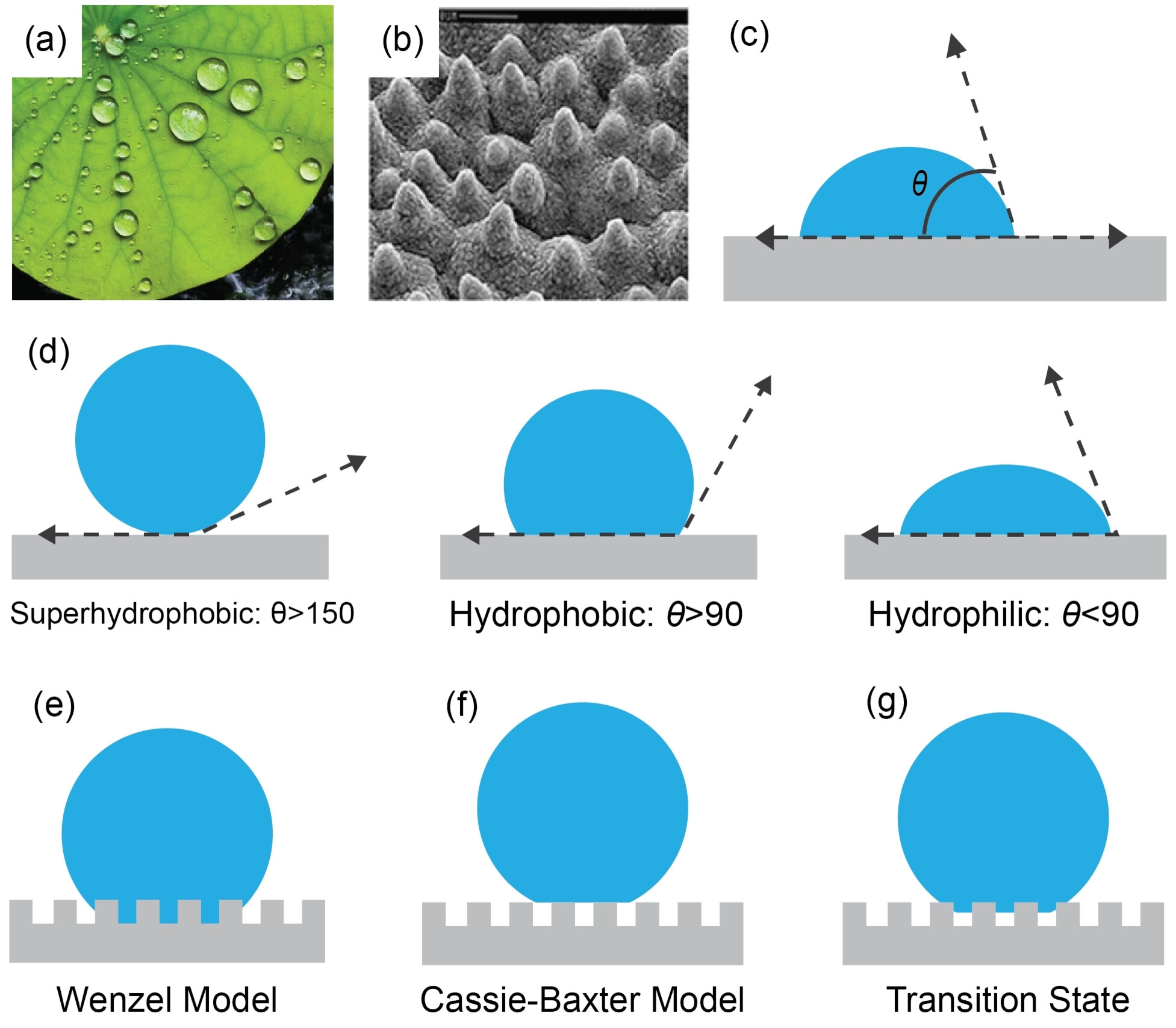

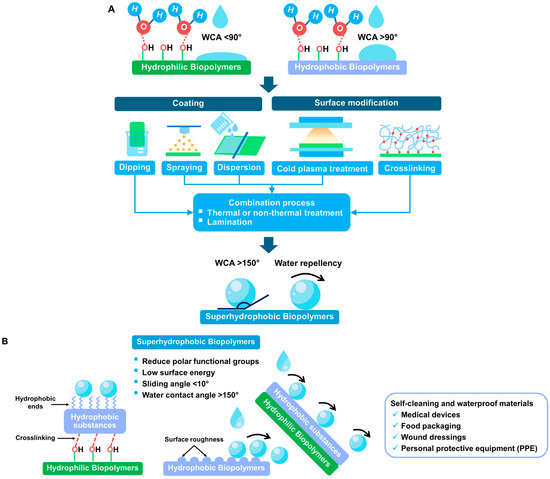

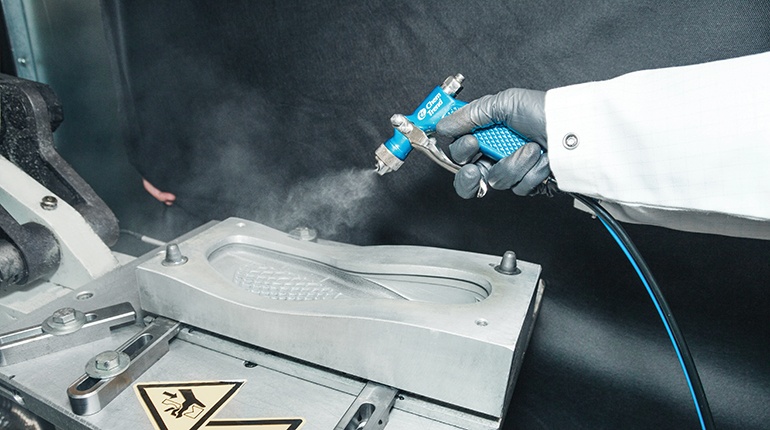

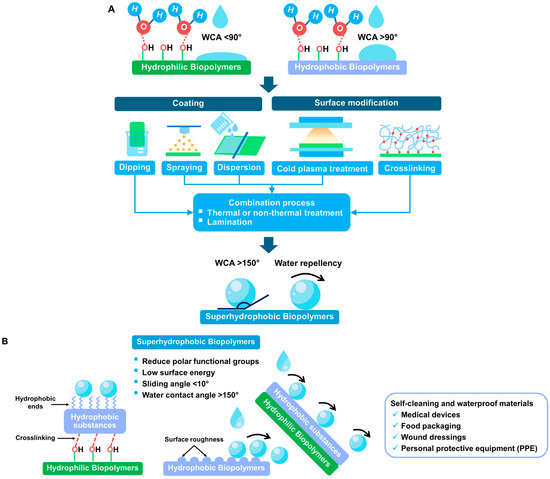

JM’s waterproofing chemicals contain ultra-fine particles ranging from 1 to 100 nanometers. When applied to shoe surfaces (fabric, leather, or mesh), these molecules self-assemble into a microscopic mountain-and-valley structure. This structure lowers the surface energy of the shoe to a level significantly lower than the surface tension of water, creating a perfect Lotus Effect.

Durable Covalent Bonding

Unlike cheap retail nano sprays that only offer temporary protection, JM’s specialized chemicals form direct covalent bonds with Cellulose fibers (in fabric) or Collagen fibers (in leather). This ensures the waterproofing layer remains intact against mechanical friction and does not wash away with standard cleaning agents.

2. JM: Tailored Waterproofing Solutions for Every Material

Every shoe material has unique physicochemical properties. Understanding this, JM has developed a specialized chemical ecosystem that ensures maximum efficiency without altering the color or texture of the product.

3. Why Should Vietnamese Manufacturers Partner with JM?

Elevating Brand Positioning

Instead of competing solely on price, integrating waterproofing features allows Vietnamese brands to enter the premium segment. Customers are willing to pay 15-30% more for shoes that are weather-ready and protected against unpredictable rain.

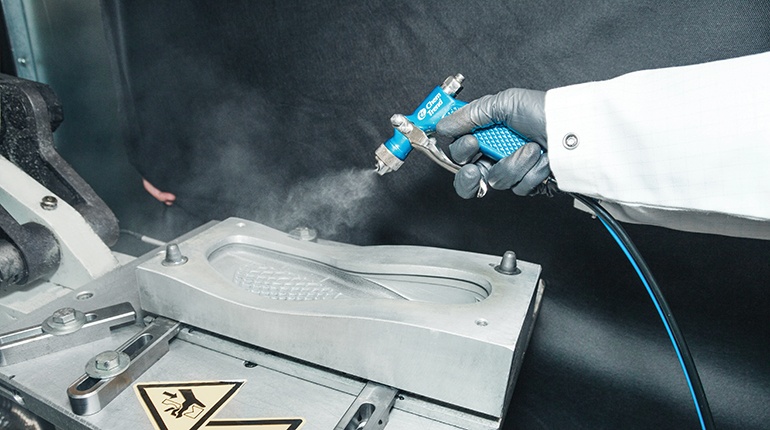

Optimizing Production Efficiency

JM’s chemicals are designed for seamless integration into existing finishing lines in Vietnamese factories. We provide on-site technical support to help businesses optimize consumption rates, thereby reducing Operating Expenses (OPEX) while achieving international quality standards.

JM Expert Insight: Nano technology is no longer a luxury; it is the new standard for the modern footwear industry. Companies that master this technology early will win the trust of global consumers.

4. Conclusion

Applying Nano-Waterproofing Technology is a strategic move to elevate the value of Made in Vietnam footwear. With JM as your technical partner, local brands can confidently compete with international giants through superior quality and innovation.

JM Enterprise – Excellence in Durability and Quality for Every Step.

📞 Contact Us Today for Quotation & Technical Advice

📍 JM ENTERPRISE

☎️ Hotline/Zalo: 84 933 706 351 Mr Cha (speak English) 84 913390054 Ms Ngan ( speak Vietnamese)

📧 Email: jhcha@jmentchemical.com

🌐 Website: https://jmentchemical.com/

Let your brand be part of the global green revolution!

Discover JM's cutting-edge nano-waterproofing chemicals. A breakthrough solution...

The JM Enterprise coating is non-film-forming. It encapsulates individual fibers...

Explore REACH and RoHS compliance for footwear accessories. Discover high-qualit...

Discover the Top 5 mold release agents for EVA shoe soles in 2026. JM Enterprise...

Learn how to reduce shoe sole defects in injection molding. Discover criteria fo...

JM Enterprise specializes in high-quality industrial outsoles, water-repellent c...

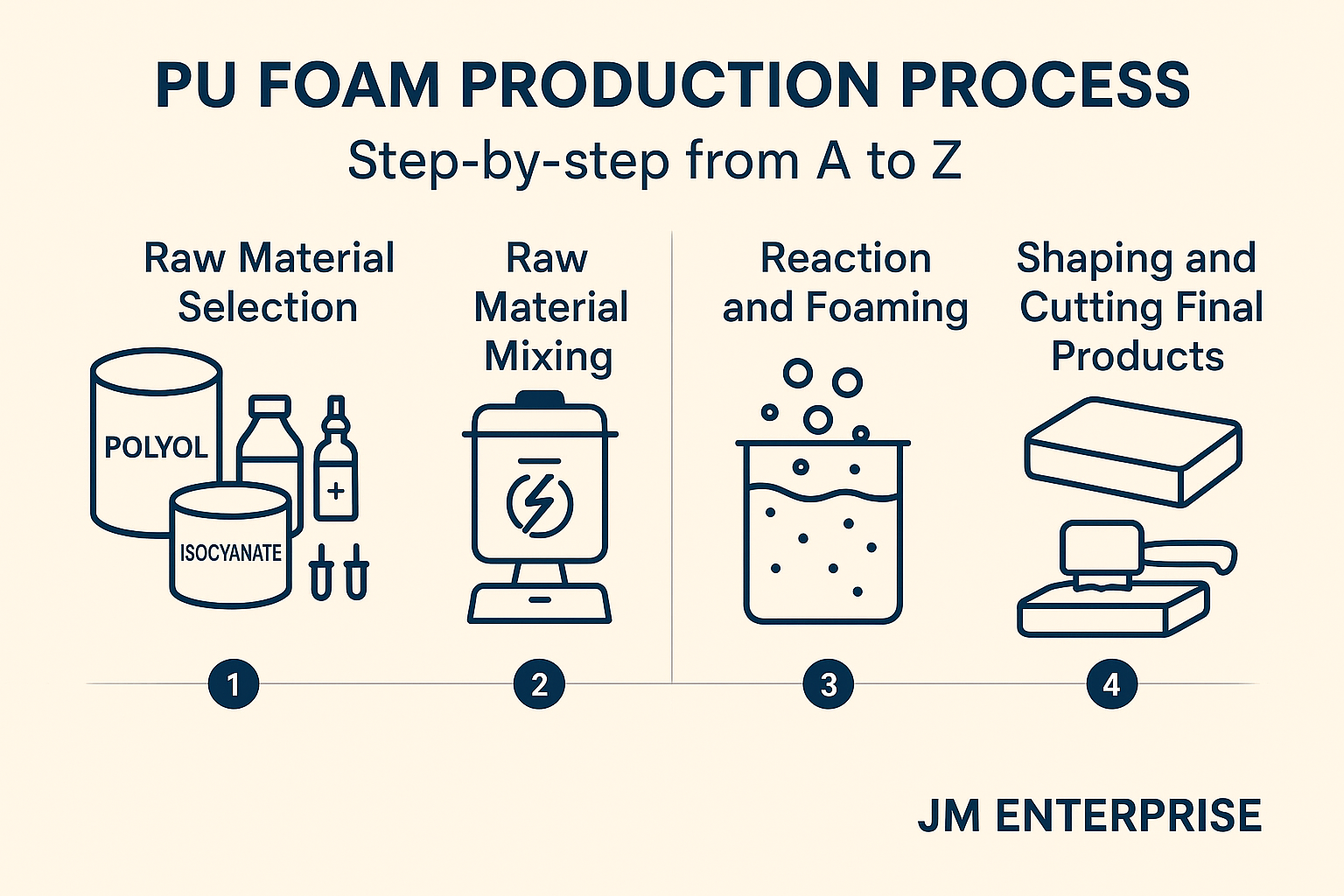

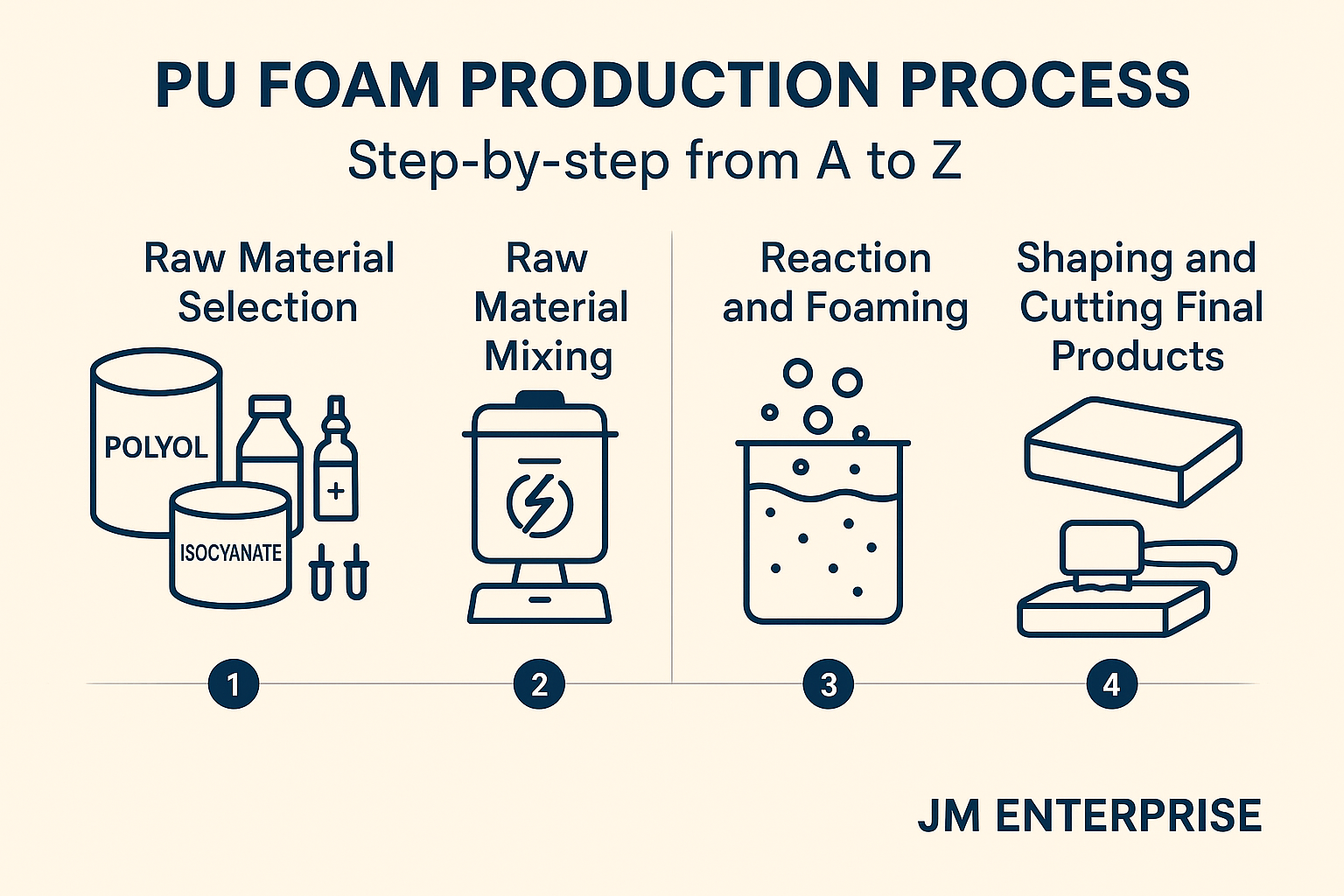

Explore the complete PU foam production process from A to Z and discover how sou...

Discover SONGWON's high-performance Anti-Oxidants for plastic compounding

How OH and oxygen content in polyol affect polyurethane performance. Learn how t...

JM Enterprise supplies high-quality MDI and TDI for PU production in Vietnam. Co...

Contact JM ENTERPRISE for high-quality raw materials, competitive prices, and ex...

Explore the top 5 adhesives for export packaging in 2025 compliant with EU & US...

Learn how to reduce shoe sole defects in injection molding. Discover criteria fo...

Discover the essential role of isocyanates in polyurethane production. JM Enterp...

Explore the complete PU foam production process from A to Z and discover how sou...

The JM Enterprise coating is non-film-forming. It encapsulates individual fibers...

Antioxidant additives play a vital role in enhancing thermal stability, extendin...

PU Foam is becoming a key material in modern interior design: lightweight, durab...

© Jmentchemical. All Rights Reserved.

Designed by HTML Codex