In the Injection Molding process for footwear, controlling the defect rate is essential for cost optimization and high productivity. One of the most critical factors is the strategic use and selection of mold release agents.

Below are 5 expert tips to help you eliminate surface flaws and deformation while enhancing the final product's quality.

5 Secrets to Reducing Surface Defects and Deformation

1. Match the Release Agent to Your Material

Different materials such as PU, TPU, EVA, or Rubber have distinct chemical properties and bonding strengths. Using an incompatible release agent can lead to mold sticking or surface degradation, resulting in cracks or discoloration.

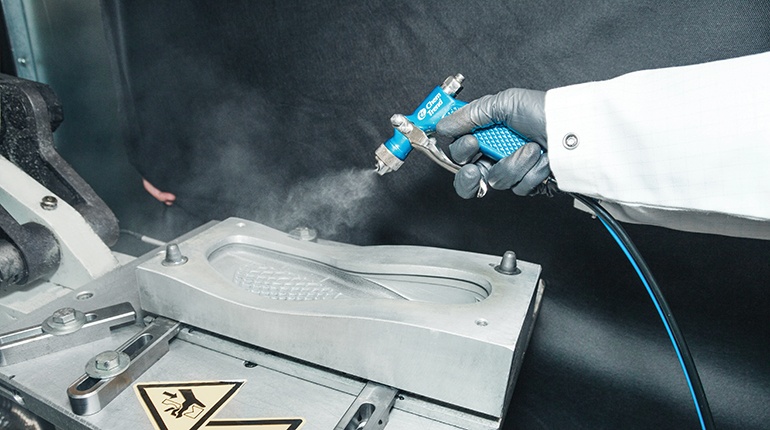

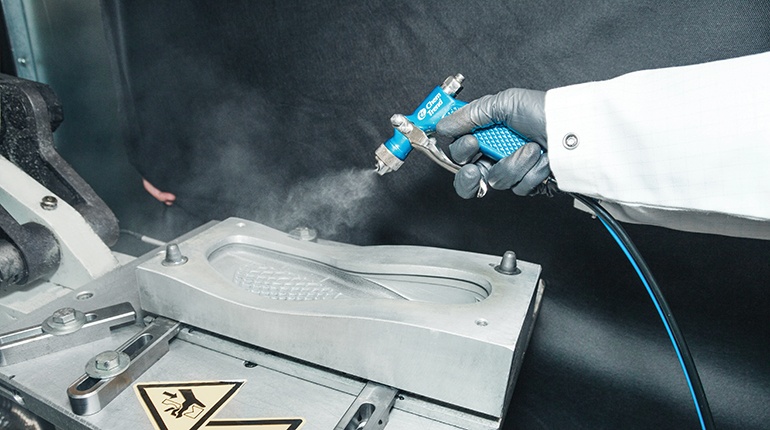

2. Utilize Fine Atomization Techniques

Avoid heavy or uneven spraying. Use high-pressure spray equipment to create a thin, consistent mist. This prevents pooling, which is the primary cause of oily patches and air bubbles on the sole surface.

3. Maintain Precise Mold Temperature

Mold release agents require a specific temperature range to form an effective protective barrier.

4. Implement Regular Preventive Maintenance

The buildup of residual chemicals and resin is a leading cause of dimensional inaccuracies and loss of texture detail. Ensure molds are cleaned periodically to remove old layers before applying new ones.

5. Optimize Spraying Frequency

Spraying after every single cycle is often unnecessary and can be counterproductive. Excess residue can interfere with the adhesive bonding of the sole to the upper later in production. Determine the optimal spray-to-cycle ratio to save costs and maintain quality.

Criteria for Selecting Water-Based Mold Release Agents

Water-based release agents are now the industry standard due to their environmental friendliness and worker safety. Consider these criteria for your specific needs:

JM Enterprise – Your Partner for TPU and Optimization Solutions

If you are seeking a trusted partner to refine your production line, JM Enterprise offers total solutions for the footwear industry:

JM Enterprise – Excellence in Durability and Quality for Every Step.

📞 Contact Us Today for Quotation & Technical Advice

📍 JM ENTERPRISE

☎️ Hotline/Zalo: 84 933 706 351 Mr Cha (speak English) 84 913390054 Ms Ngan ( speak Vietnamese)

📧 Email: jhcha@jmentchemical.com

🌐 Website: https://jmentchemical.com/

🌿 Choose sustainable packaging today — drive long-term business growth tomorrow.

Let your brand be part of the global green revolution!

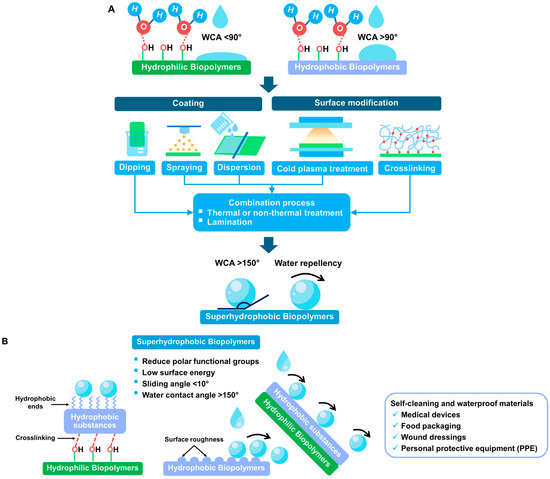

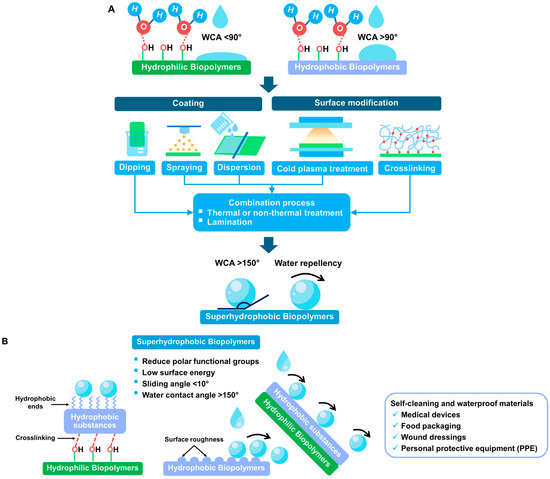

Discover JM's cutting-edge nano-waterproofing chemicals. A breakthrough solution...

The JM Enterprise coating is non-film-forming. It encapsulates individual fibers...

Explore REACH and RoHS compliance for footwear accessories. Discover high-qualit...

Discover the Top 5 mold release agents for EVA shoe soles in 2026. JM Enterprise...

Learn how to reduce shoe sole defects in injection molding. Discover criteria fo...

JM Enterprise specializes in high-quality industrial outsoles, water-repellent c...

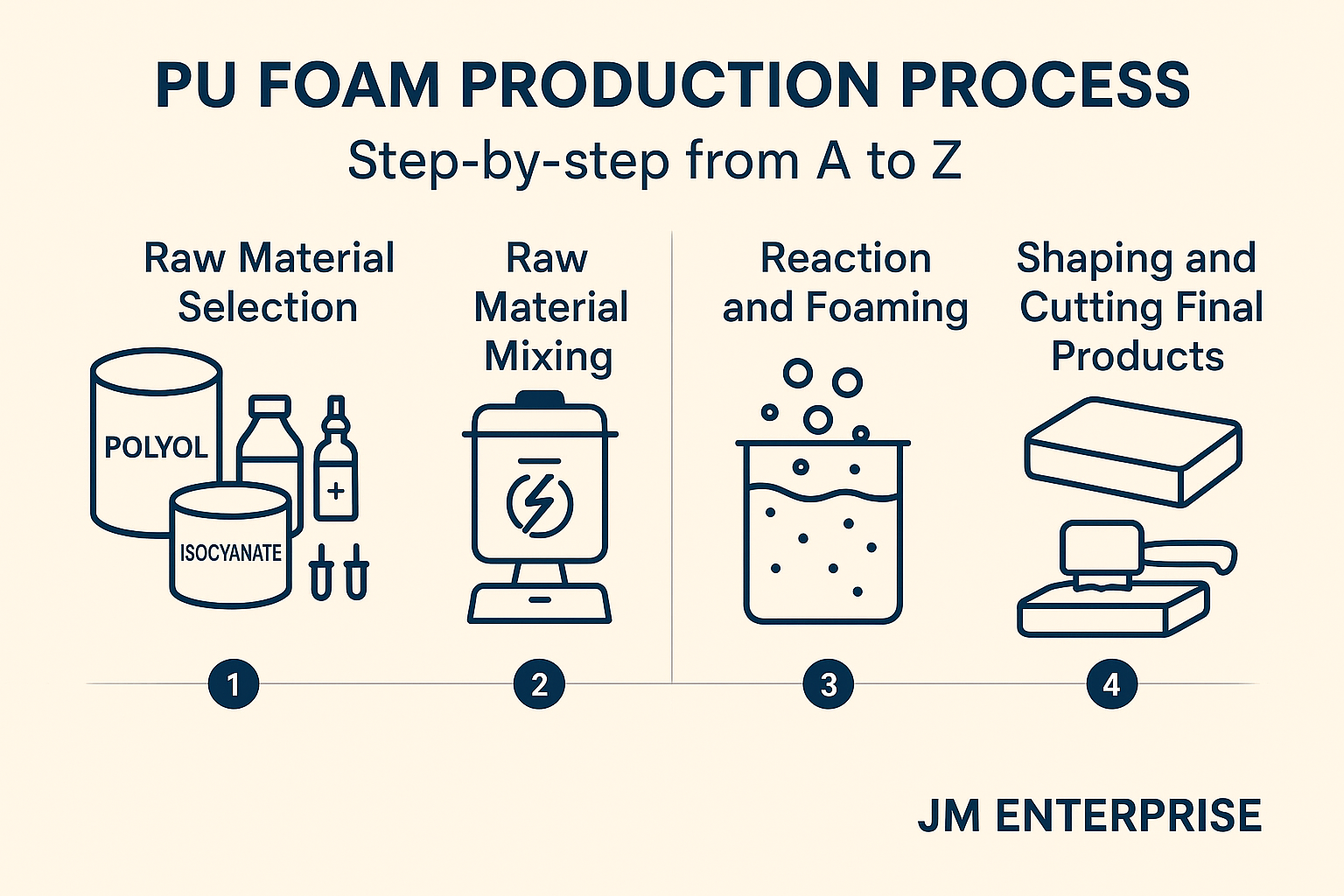

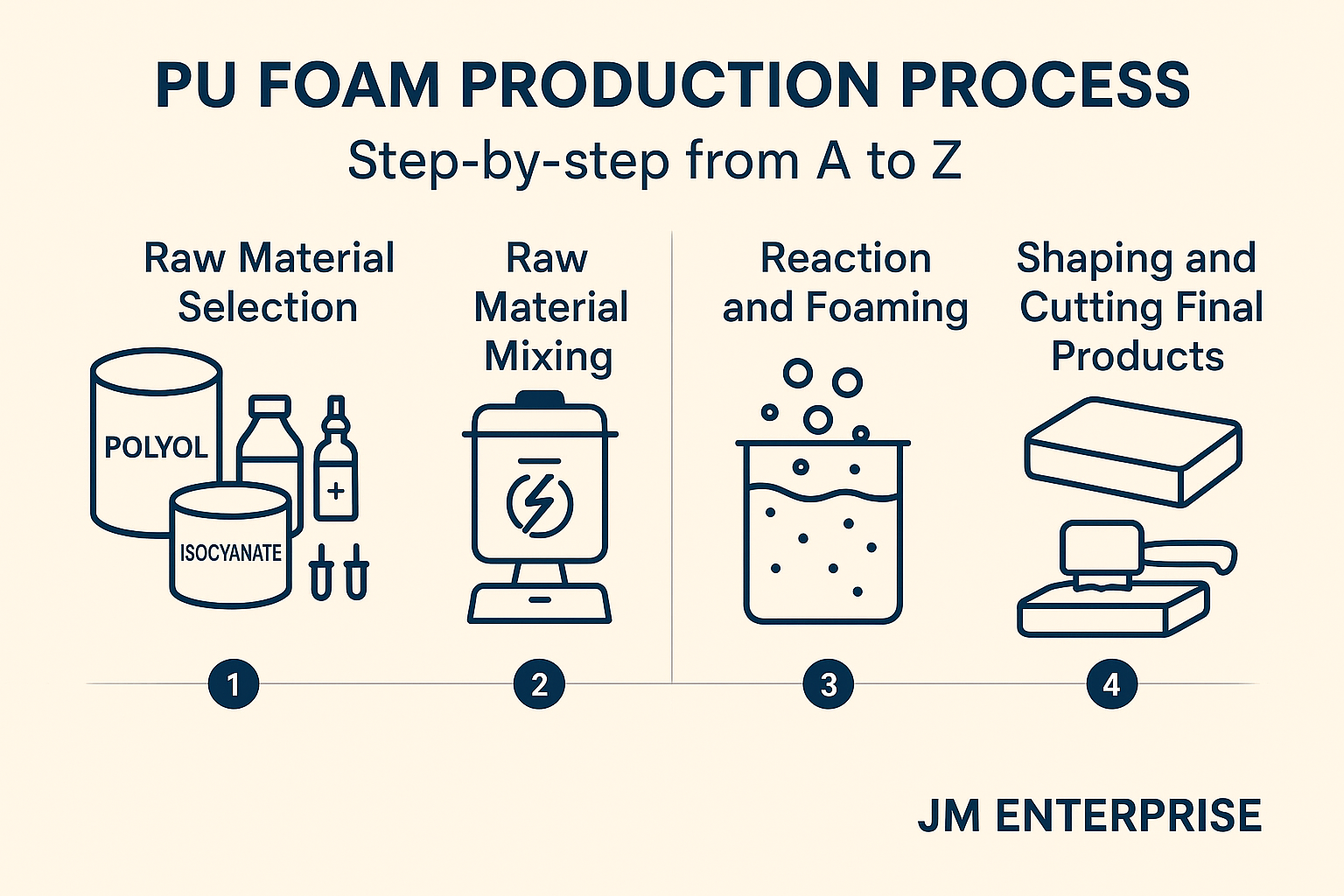

Explore the complete PU foam production process from A to Z and discover how sou...

Discover SONGWON's high-performance Anti-Oxidants for plastic compounding

How OH and oxygen content in polyol affect polyurethane performance. Learn how t...

JM Enterprise supplies high-quality MDI and TDI for PU production in Vietnam. Co...

Contact JM ENTERPRISE for high-quality raw materials, competitive prices, and ex...

Explore the top 5 adhesives for export packaging in 2025 compliant with EU & US...

Discover the essential role of isocyanates in polyurethane production. JM Enterp...

Explore the complete PU foam production process from A to Z and discover how sou...

The JM Enterprise coating is non-film-forming. It encapsulates individual fibers...

Antioxidant additives play a vital role in enhancing thermal stability, extendin...

PU Foam is becoming a key material in modern interior design: lightweight, durab...

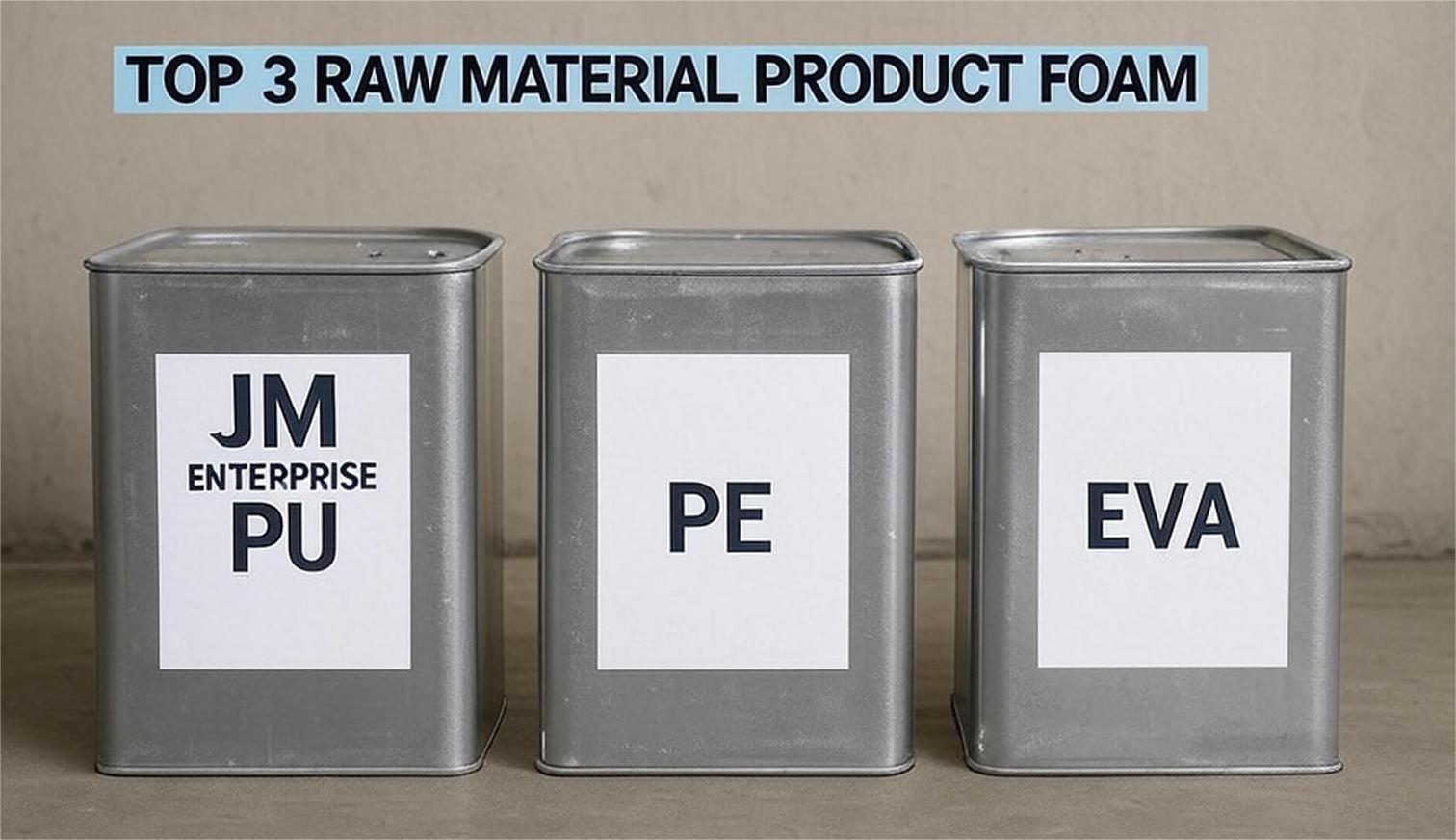

Top 3 Foam Raw Materials for Modern Industry. Why PU Foam Leads the Market – Com...

© Jmentchemical. All Rights Reserved.

Designed by HTML Codex