1. Technical Analysis: Water Repellency Mechanism of JM Enterprise Chemicals

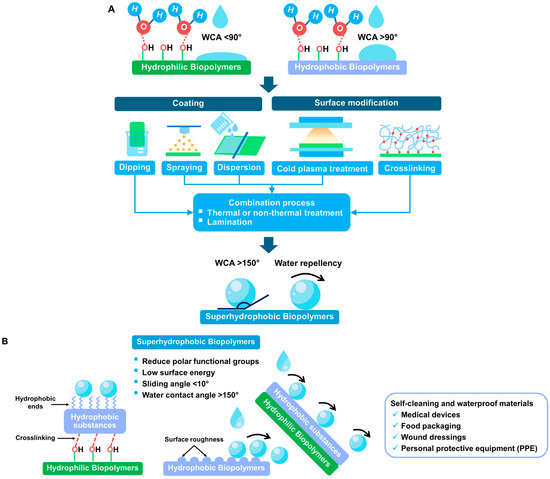

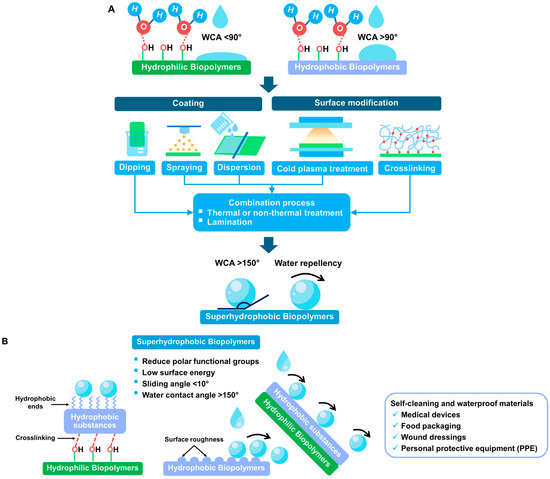

Unlike traditional waterproof waxes that clog fabric pores, JM Enterprise chemicals function through a sophisticated surface energy modification at the molecular level.

The Nano-Spike Mechanism (Lotus Effect)

When fabric is treated with JM Enterprise chemicals, the fluorocarbon (or fluorine-free) polymers self-assemble into a microscopic forest of spikes.

Air Permeability (Breathability)

The JM Enterprise coating is non-film-forming. It encapsulates individual fibers rather than sealing the gaps between them. This allows water vapor molecules (perspiration) to escape while preventing liquid droplets (rain, spills) from penetrating.

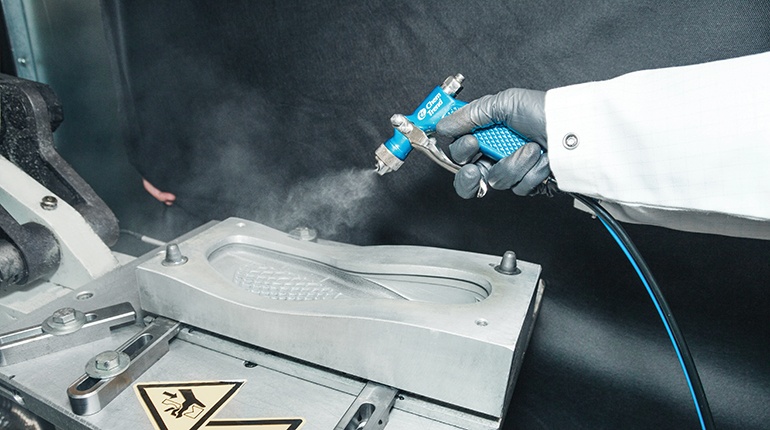

2. Standard Operating Procedure (SOP) for Factory Application

To achieve optimal water repellency and high laundry durability, technicians must adhere to the following processing steps:

Step 1: Pre-treatment

The fabric must be entirely free of impurities, sizing agents, and residual dyeing auxiliaries. These residues can interfere with the cross-linking between the JM chemical and the textile fibers.

Step 2: Padding Bath Preparation

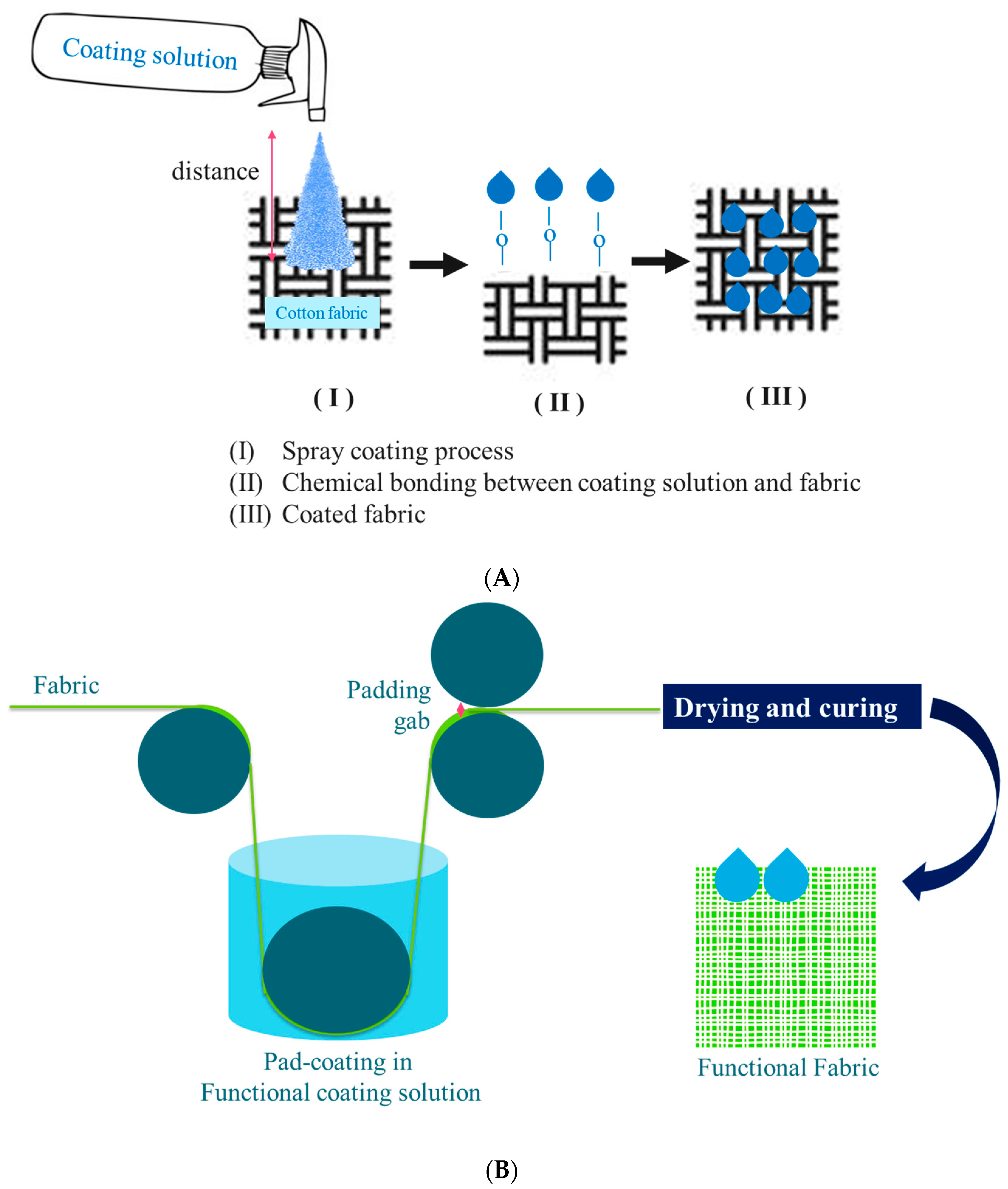

Step 3: Padding

Use a padding mangle with calculated nip pressure to achieve a wet pick-up (WPU) of 60% - 80%.

Step 4: Drying and Curing

This is the critical stage for activating water-repellent properties:

3. Quality Control Standards (Testing)

JM Enterprise chemicals are engineered to meet the most stringent international standards:

4. Technical Troubleshooting Guide

|

Issue |

Potential Cause |

JM Technical Solution |

|

Uneven Repellency |

Residual sizing or impurities. |

Enhance pre-treatment washing processes. |

|

Poor Wash Durability |

Insufficient Curing temperature. |

Verify actual fabric temperature inside the stenter. |

|

Yellowing (Fabric Discoloration) |

Temperature too high or improper pH. |

Lower curing temperature, increase dwell time, or adjust pH to 5.0. |

|

Harsh Hand-feel |

Excessively high concentration. |

Re-calibrate the recipe and check water hardness. |

5. Contact JM Enterprise Technical Support

JM Enterprise – Excellence in Durability and Quality for Every Step.

📞 Contact Us Today for Quotation & Technical Advice

📍 JM ENTERPRISE

☎️ Hotline/Zalo: 84 933 706 351 Mr Cha (speak English) 84 913390054 Ms Ngan ( speak Vietnamese)

📧 Email: jhcha@jmentchemical.com

🌐 Website: https://jmentchemical.com/

Let your brand be part of the global green revolution!

Discover JM's cutting-edge nano-waterproofing chemicals. A breakthrough solution...

The JM Enterprise coating is non-film-forming. It encapsulates individual fibers...

Explore REACH and RoHS compliance for footwear accessories. Discover high-qualit...

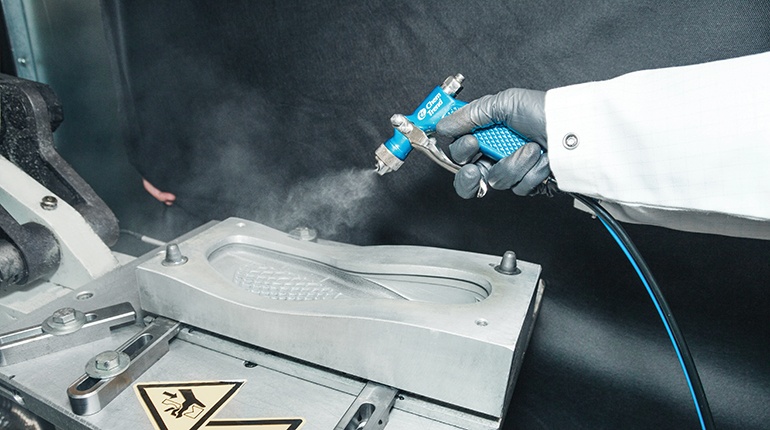

Discover the Top 5 mold release agents for EVA shoe soles in 2026. JM Enterprise...

Learn how to reduce shoe sole defects in injection molding. Discover criteria fo...

JM Enterprise specializes in high-quality industrial outsoles, water-repellent c...

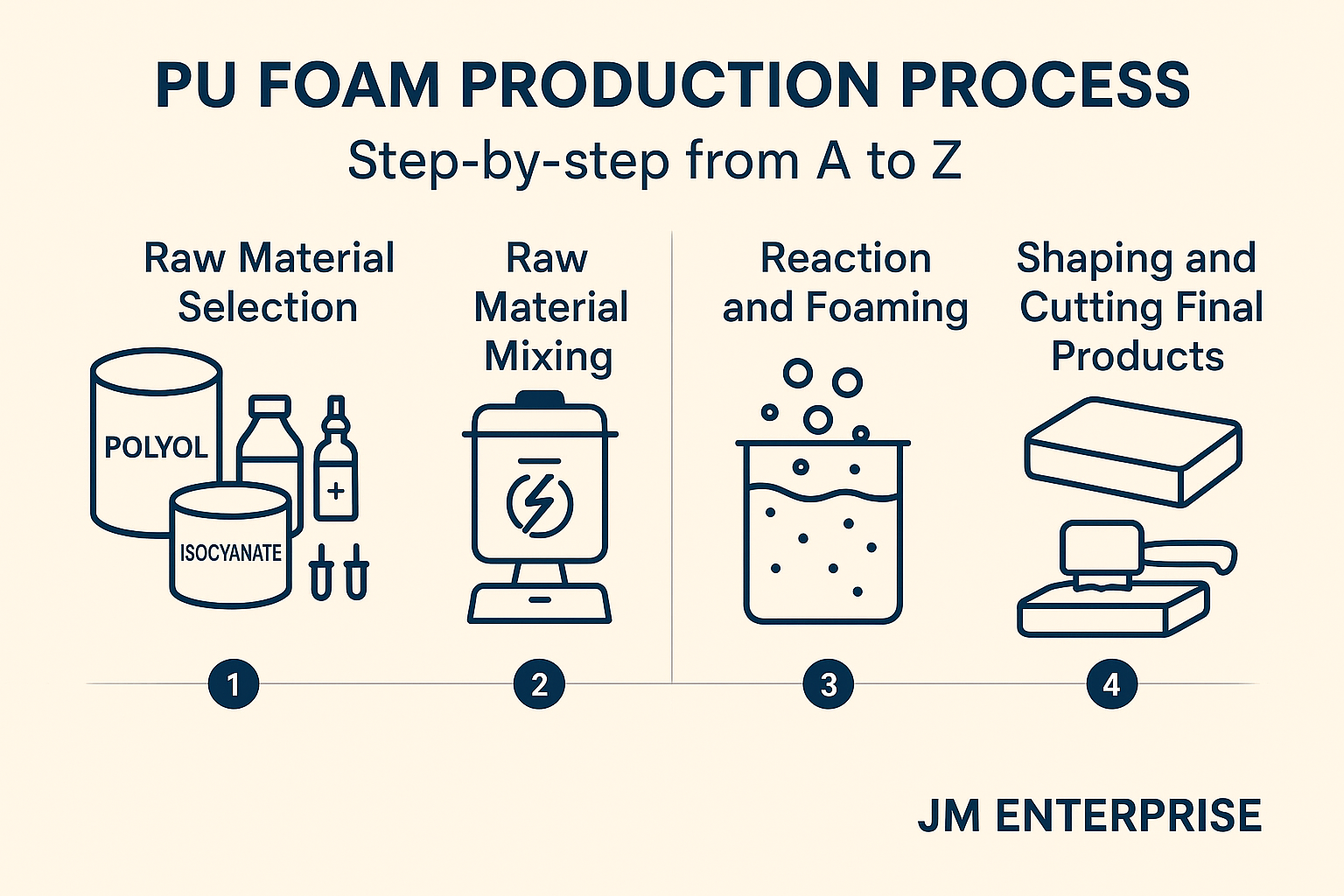

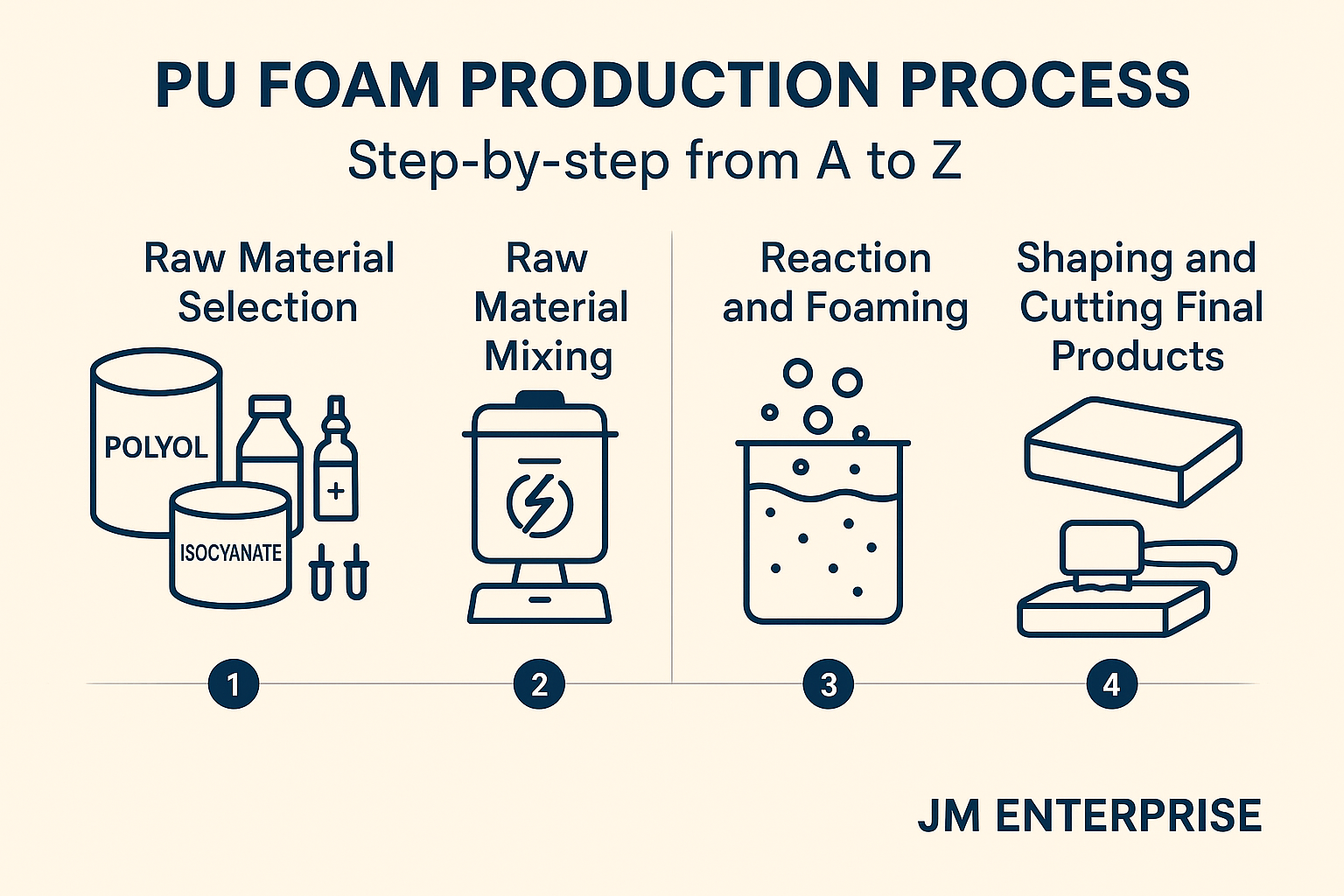

Explore the complete PU foam production process from A to Z and discover how sou...

Discover SONGWON's high-performance Anti-Oxidants for plastic compounding

How OH and oxygen content in polyol affect polyurethane performance. Learn how t...

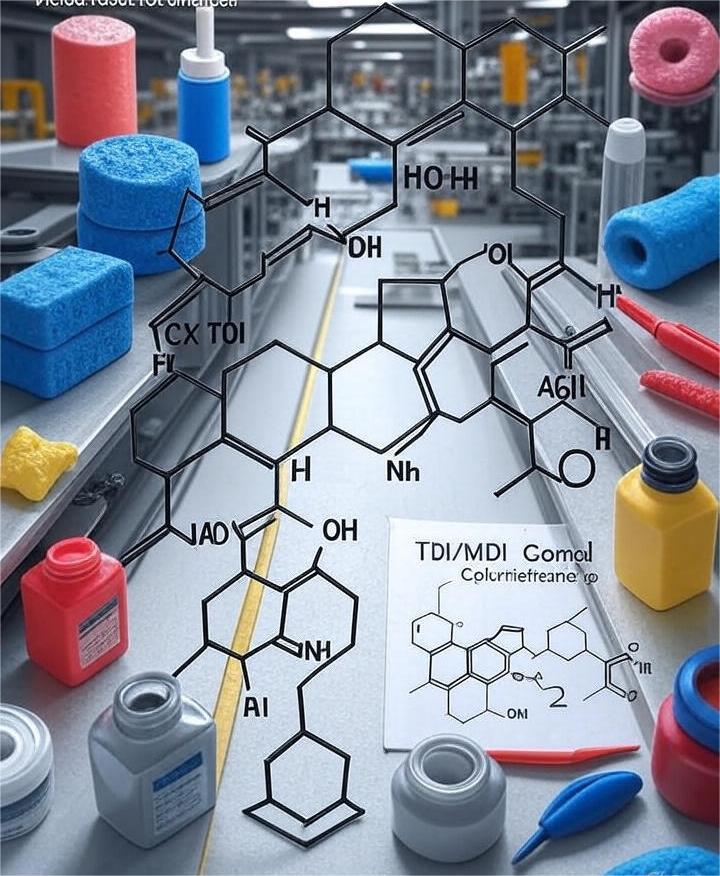

JM Enterprise supplies high-quality MDI and TDI for PU production in Vietnam. Co...

Contact JM ENTERPRISE for high-quality raw materials, competitive prices, and ex...

Explore the top 5 adhesives for export packaging in 2025 compliant with EU & US...

JM Enterprise specializes in high-quality industrial outsoles, water-repellent c...

Discover the Top 5 mold release agents for EVA shoe soles in 2026. JM Enterprise...

Discover JM's cutting-edge nano-waterproofing chemicals. A breakthrough solution...

Learn how to reduce shoe sole defects in injection molding. Discover criteria fo...

Discover the essential role of isocyanates in polyurethane production. JM Enterp...

Explore the complete PU foam production process from A to Z and discover how sou...

© Jmentchemical. All Rights Reserved.

Designed by HTML Codex