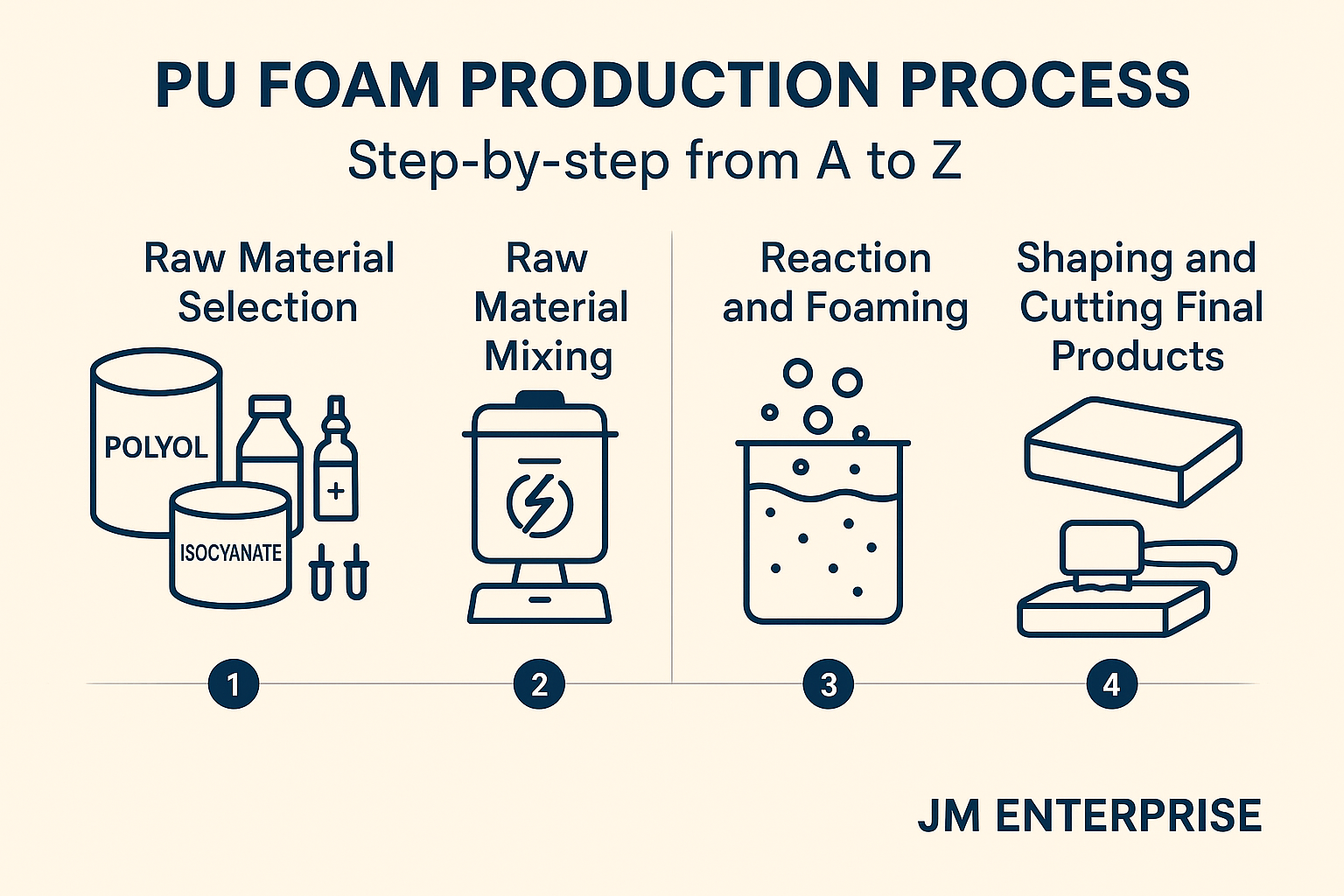

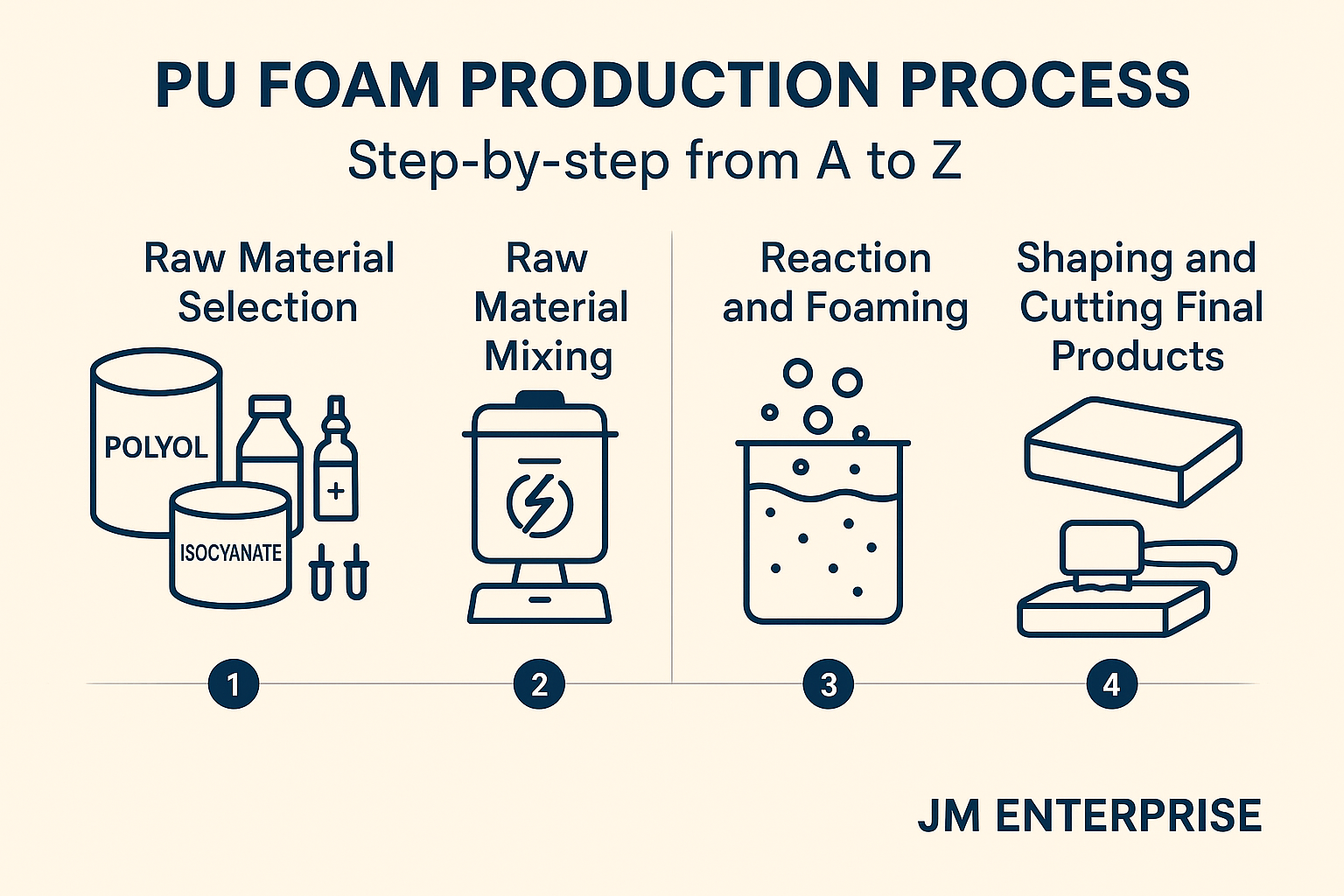

Source Certified Raw Materials from JM ENTERPRISE – The Smart Solution for PU Foam Manufacturing

Polyurethane (PU) foam plays a vital role in industries such as furniture, bedding, insulation, and packaging. To ensure high-quality foam products, mastering the production process and sourcing standardized raw materials are crucial. Let JM ENTERPRISE guide you through every step of PU foam production and provide optimized material solutions for your business!

Key raw materials used in PU foam production include:

✅ JM ENTERPRISE supplies a full range of high-quality raw materials with clear origin and international certification, ensuring consistent quality and cost-efficiency.

Once prepared, raw materials are fed into specialized mixing equipment for:

JM ENTERPRISE provides technical formulation support tailored to each application, saving you valuable R&D time.

When polyol and isocyanates are mixed, a chemical reaction creates polymer chains and CO₂ gas, forming foam:

🧪 With JM ENTERPRISE’s raw materials, the foaming reaction is controlled, consistent, and reliable, minimizing production variability.

After foaming, the material is:

JM ENTERPRISE offers tailored material recommendations to ensure optimal performance for your end products.

Final foam products undergo testing for:

Every JM ENTERPRISE product is accompanied by complete COA & MSDS documentation, making compliance easy and reliable.

✅ Consistent quality – Competitive pricing – Fast delivery

✅ On-site technical support & formulation consulting

✅ Comprehensive portfolio: PPG, POP, TDI, MDI, catalysts, additives...

✅ Flexible supply: small trial batches, free sampling support

📞 Contact Us Now for Technical Consultation & Quotation:

☎️ Hotline/Zalo: 84 933 706 351 Mr Cha (speak English and Korean) 84 913390054 Ms Ngan ( speak Vietnamese)

📧 Email: jhcha@jmentchemical.com

🌐 Website: https://jmentchemical.com/

🌿 Choose sustainable packaging today — drive long-term business growth tomorrow.

Let your brand be part of the global green revolution!

As electricity prices continue to rise and green-building regulations become str...

In today's modern industry, PU Foam chemicals (Polyurethane Foam) have become th...

TPU for heavy-duty wheels helps extend lifespan by 2–3 times compared to PU. JM...

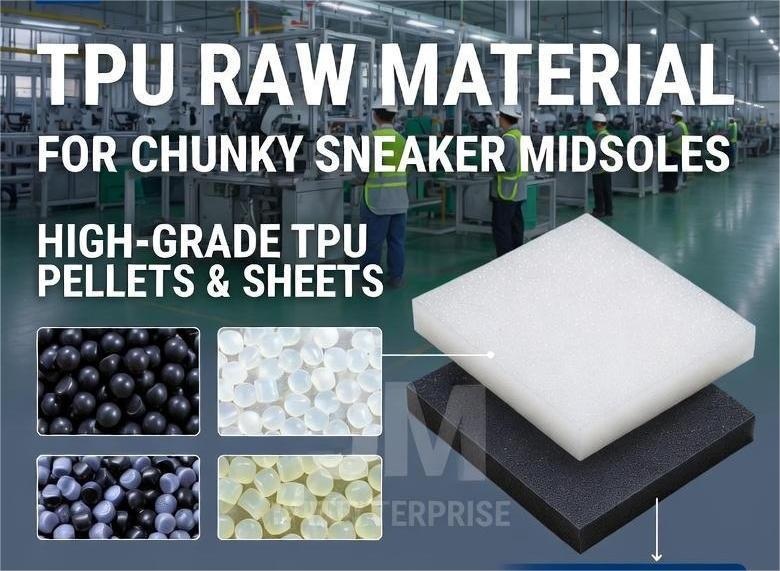

2025 is the breakthrough year for Vietnamese footwear factories to level up with...

Discover the key differences between memory foam and HR foam in pillows. Compare...

Discover why shockproof TPU phone cases are increasingly popular. JM ENTERPRISE...

Explore the complete PU foam production process from A to Z and discover how sou...

Discover SONGWON's high-performance Anti-Oxidants for plastic compounding

How OH and oxygen content in polyol affect polyurethane performance. Learn how t...

JM Enterprise supplies high-quality MDI and TDI for PU production in Vietnam. Co...

Contact JM ENTERPRISE for high-quality raw materials, competitive prices, and ex...

Under direct sunlight—especially in high UV-index regions like Vietnam and South...

The JM Enterprise – BNI Connect partnership marks a milestone in expanding busin...

As electricity prices continue to rise and green-building regulations become str...

Discover polyurethane foam in car seats – a modern material imported from Korea...

Under direct sunlight—especially in high UV-index regions like Vietnam and South...

Buy high-purity TDI from Hanwha at the best price. Ideal for PU foam, adhesives,...

Discover whether TPU is truly eco-friendly, its recyclability, product life cycl...

© Jmentchemical. All Rights Reserved.

Designed by HTML Codex