Polyol is a compound containing multiple hydroxyl (-OH) groups that reacts with isocyanate (NCO) to form urethane linkages, the backbone of all polyurethane (PU) materials.

The OH value (hydroxyl number) and oxygen content in the polyol structure directly influence:

💡 Definition:

The hydroxyl number measures the amount of hydroxyl groups in a polyol, expressed in mg KOH per gram of polyol.

🎯 Technical Implications:

Real-world examples:

NCO:OH Ratio:

Polyols contain oxygen atoms in ether (-O-) or ester (-COO-) bonds, depending on the type.

💡 Comparison:

|

Polyol Type |

Structure |

Key Features |

|

Polyether Polyol |

Ether (-O-) |

Fast-reacting, hydrolysis-resistant |

|

Polyester Polyol |

Ester (-COO-) |

Strong adhesion, hard, prone to hydrolysis |

🔬 Technical Effects:

🛠️ Application Examples Based on OH and Oxygen Content

|

Application |

Polyol Type |

OH Number |

Oxygen Structure |

Target Properties |

|

Flexible foam (seats, beds) |

Polyether polyol |

28–45 |

Ether |

Softness, elasticity, water resistance |

|

Rigid foam (insulation) |

Polyether or polyester polyol |

350–500 |

Ether/Ester |

High rigidity, thermal insulation |

|

PU Adhesives & Coatings |

Polyester polyol |

100–300 |

Ester |

Strong bonding, chemical resistance |

|

Exterior PU Coatings |

Polyester + UV stabilizers |

200–400 |

Ester |

UV durability, weather resistance |

🧪 Best Practices in PU Formulation:

✅ Conclusion: Optimizing OH and Oxygen Content is Essential for Superior PU Quality

Understanding and adjusting the OH value and oxygen structure of polyols is crucial for successful polyurethane formulation. Whether you're producing flexible foam, rigid insulation, coatings, or adhesives, these two parameters determine the durability, performance, and cost-efficiency of your PU product.

📞 Need Technical Support or Cost-Effective Polyol Solutions?

JM ENTERPRISE is a trusted manufacturer and supplier of polyurethane-grade chemicals in Vietnam – offering:

👉 Contact JM ENTERPRISE today to get a free consultation and customized quotation for your polyurethane production.

Hotline/Zalo: 84 933 706 351 Mr Cha (speak English and Korea) 84 913390054 Ms Ngan ( speak Vietnamese)

📧 Email: jhcha@jmentchemical.com

🌐 Website: https://jmentchemical.com/

🌿 Choose sustainable packaging today — drive long-term business growth tomorrow.

Let your brand be part of the global green revolutio

As electricity prices continue to rise and green-building regulations become str...

In today's modern industry, PU Foam chemicals (Polyurethane Foam) have become th...

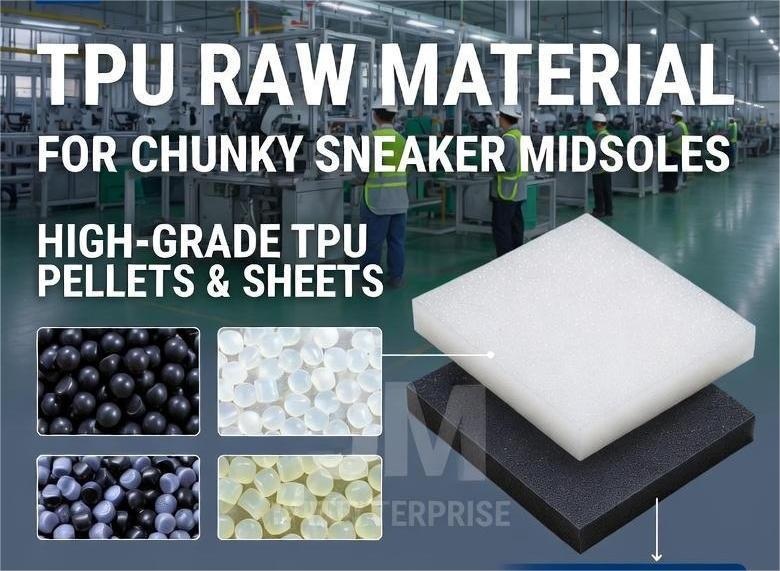

TPU for heavy-duty wheels helps extend lifespan by 2–3 times compared to PU. JM...

2025 is the breakthrough year for Vietnamese footwear factories to level up with...

Discover the key differences between memory foam and HR foam in pillows. Compare...

Discover why shockproof TPU phone cases are increasingly popular. JM ENTERPRISE...

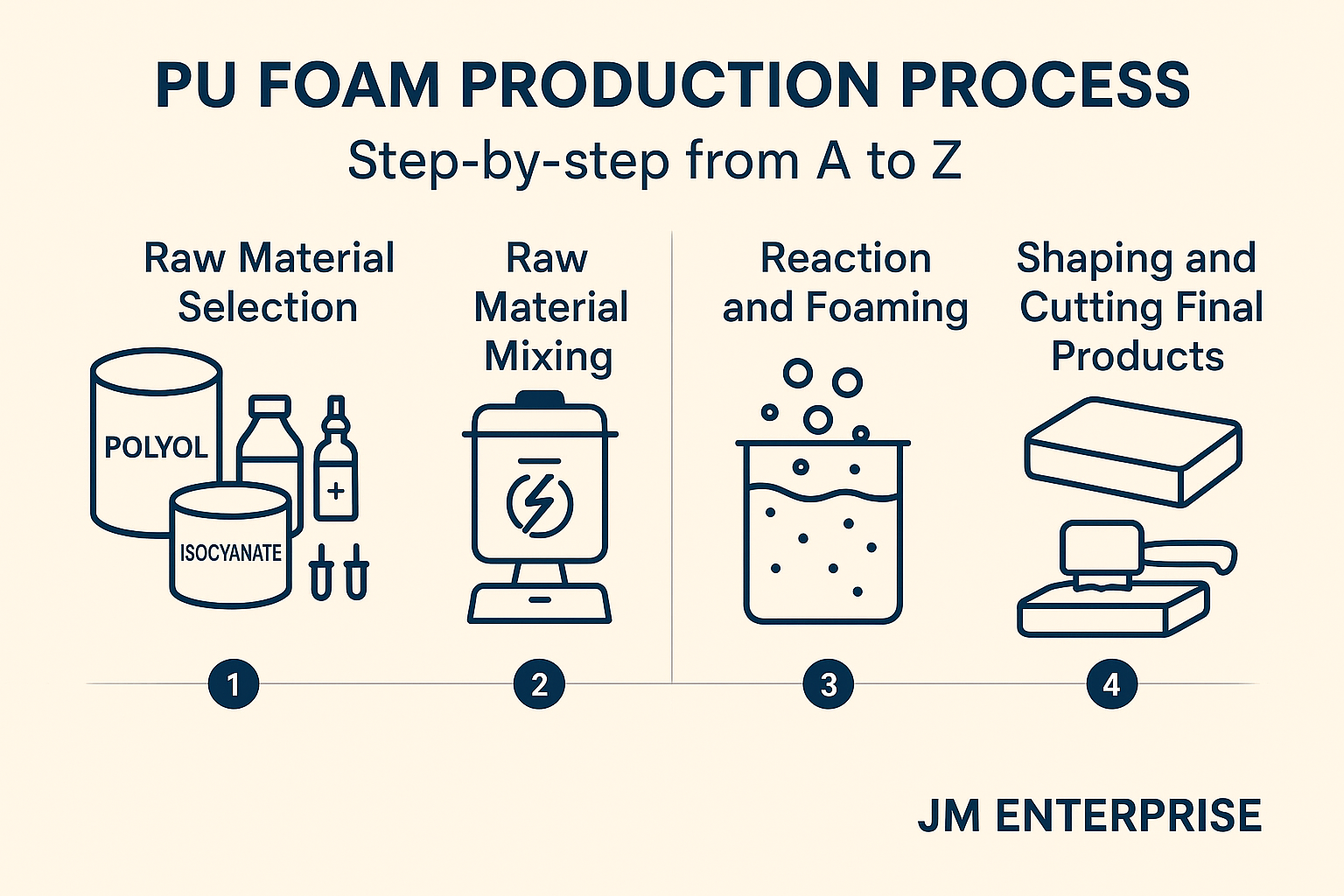

Explore the complete PU foam production process from A to Z and discover how sou...

Discover SONGWON's high-performance Anti-Oxidants for plastic compounding

How OH and oxygen content in polyol affect polyurethane performance. Learn how t...

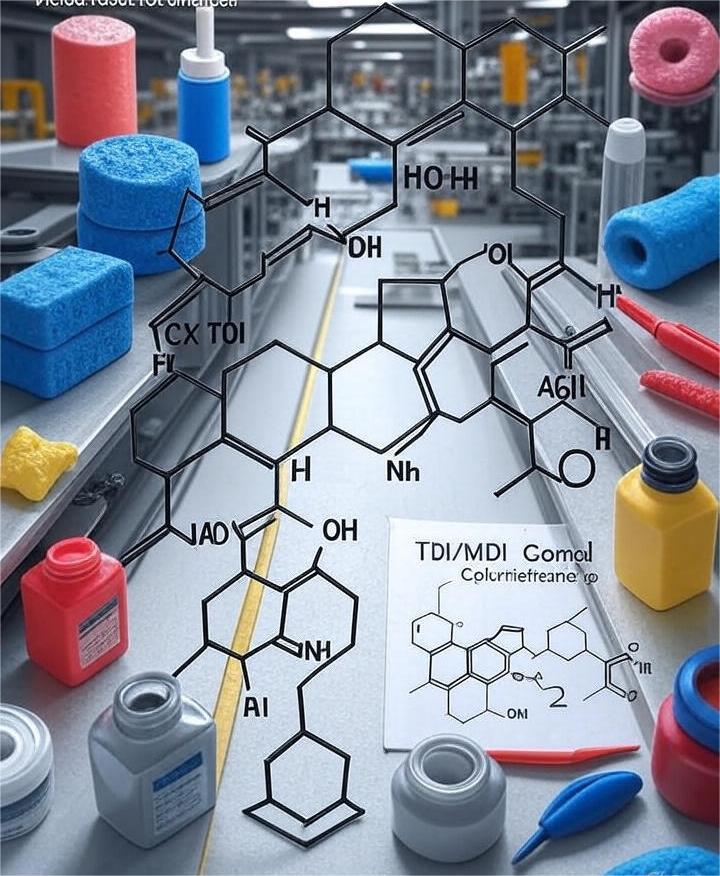

JM Enterprise supplies high-quality MDI and TDI for PU production in Vietnam. Co...

Contact JM ENTERPRISE for high-quality raw materials, competitive prices, and ex...

Under direct sunlight—especially in high UV-index regions like Vietnam and South...

Under direct sunlight—especially in high UV-index regions like Vietnam and South...

Discover SONGWON's high-performance Anti-Oxidants for plastic compounding

Discover why shockproof TPU phone cases are increasingly popular. JM ENTERPRISE...

Explore the top 5 adhesives for export packaging in 2025 compliant with EU & US...

In today's modern industry, PU Foam chemicals (Polyurethane Foam) have become th...

The JM Enterprise – BNI Connect partnership marks a milestone in expanding busin...

© Jmentchemical. All Rights Reserved.

Designed by HTML Codex