Table of Contents

Polyol is a polyhydric compound containing multiple hydroxyl groups (-OH) that react with isocyanates (-NCO) to form polyurethane. It is the primary component in most PU formulations by volume.

There are two common types of polyol:

The quality of polyol directly affects:

Using unstable or low-grade polyol can result in:

Controlling polyol quality means controlling the final PU product quality.

JM ENTERPRISE provide industry-grade polyol with:

✅ Our team offers full technical support to help you optimize formulation, minimize production defects, and reduce overall cost.

Contact JM ENTERPRISE today for consultation and free samples

Hotline/Zalo: 84 933 706 351 Mr Cha (speak English and Korea) 84 913390054 Ms Ngan ( speak Vietnamese)

Email: jhcha@jmentchemical.com

Website: https://jmentchemical.com/

Choose sustainable packaging today — drive long-term business growth tomorrow.

Let your brand be part of the global green revolutio

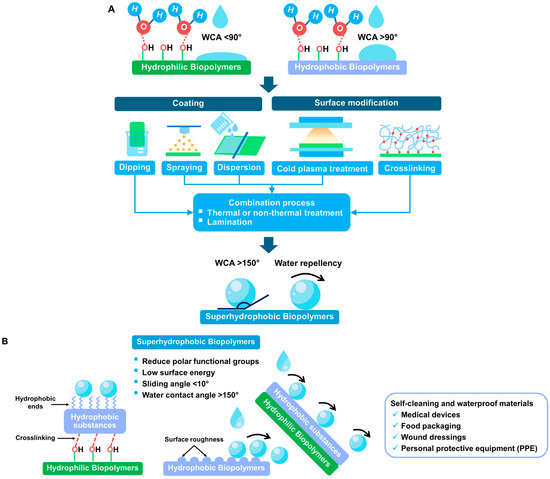

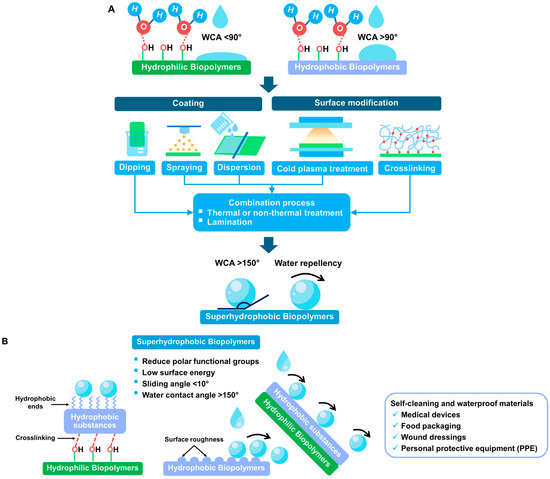

Discover JM's cutting-edge nano-waterproofing chemicals. A breakthrough solution...

The JM Enterprise coating is non-film-forming. It encapsulates individual fibers...

Explore REACH and RoHS compliance for footwear accessories. Discover high-qualit...

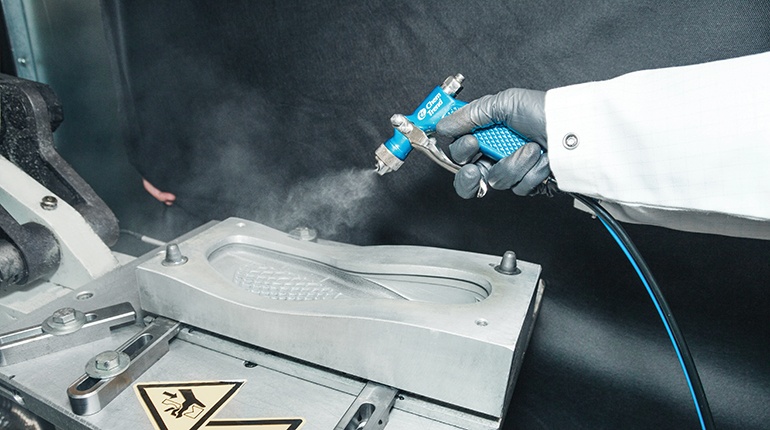

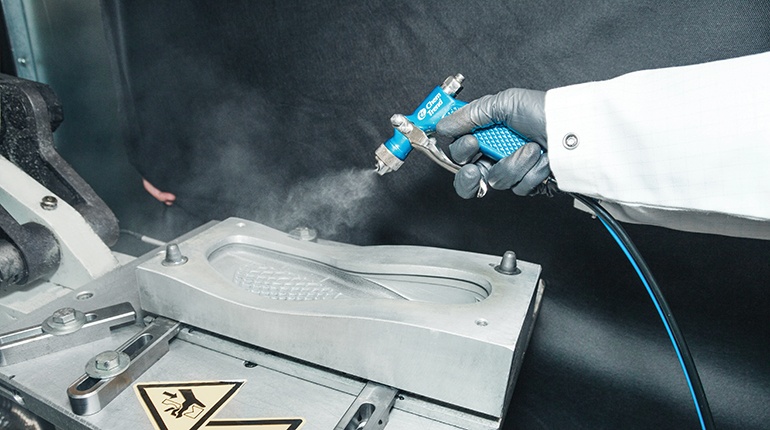

Discover the Top 5 mold release agents for EVA shoe soles in 2026. JM Enterprise...

Learn how to reduce shoe sole defects in injection molding. Discover criteria fo...

JM Enterprise specializes in high-quality industrial outsoles, water-repellent c...

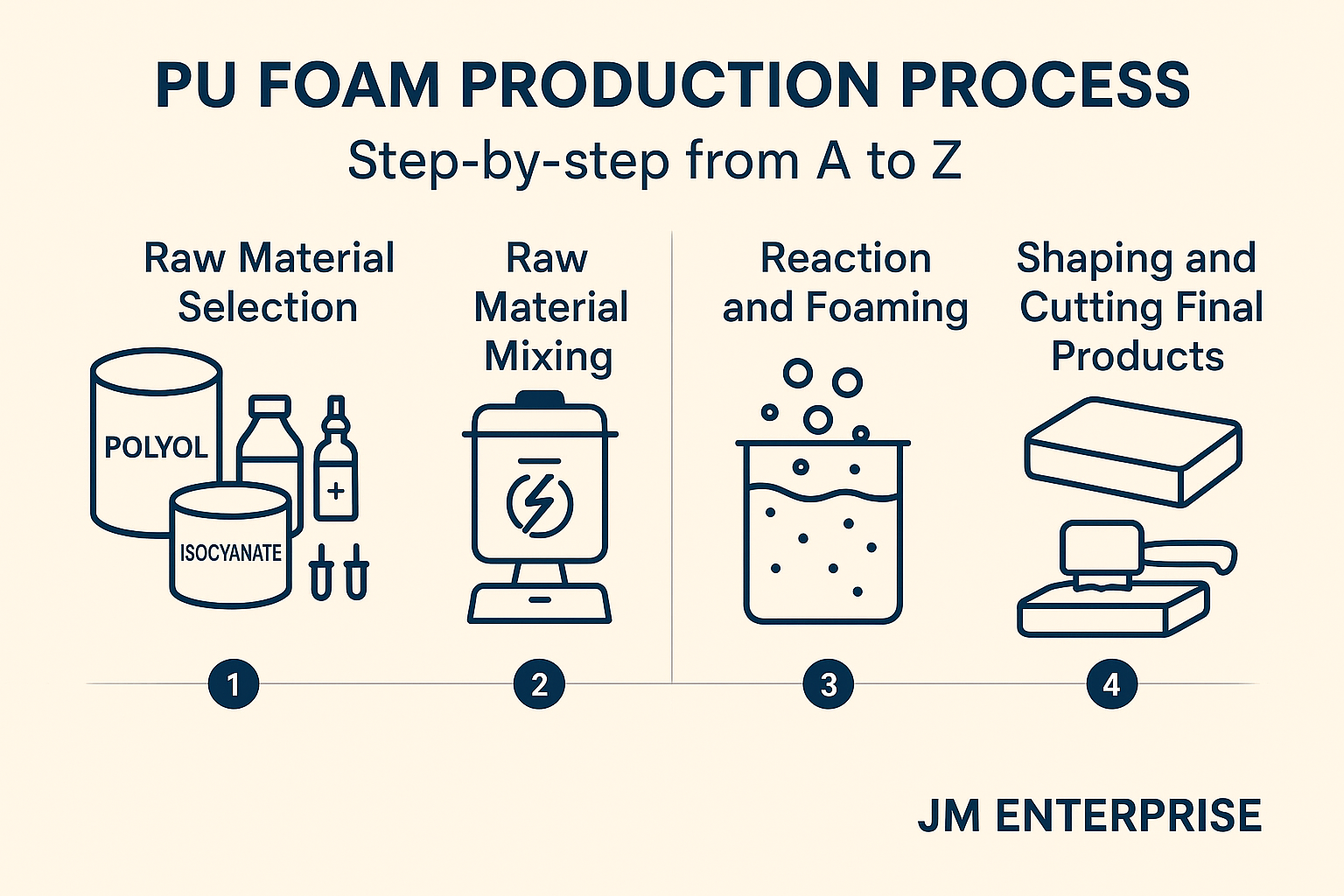

Explore the complete PU foam production process from A to Z and discover how sou...

Discover SONGWON's high-performance Anti-Oxidants for plastic compounding

How OH and oxygen content in polyol affect polyurethane performance. Learn how t...

JM Enterprise supplies high-quality MDI and TDI for PU production in Vietnam. Co...

Contact JM ENTERPRISE for high-quality raw materials, competitive prices, and ex...

Explore the top 5 adhesives for export packaging in 2025 compliant with EU & US...

Explore REACH and RoHS compliance for footwear accessories. Discover high-qualit...

The JM Enterprise coating is non-film-forming. It encapsulates individual fibers...

JM Enterprise specializes in high-quality industrial outsoles, water-repellent c...

Discover the Top 5 mold release agents for EVA shoe soles in 2026. JM Enterprise...

Discover JM's cutting-edge nano-waterproofing chemicals. A breakthrough solution...

Learn how to reduce shoe sole defects in injection molding. Discover criteria fo...

© Jmentchemical. All Rights Reserved.

Designed by HTML Codex