TPU and Sustainability: Is It an Eco-Friendly Material?

As global industries increasingly prioritize environmental protection, the search for materials that are both high-performing and sustainable has intensified. Thermoplastic Urethane (TPU) has emerged as a promising solution due to its recyclability and sustainable properties. But is TPU truly eco-friendly? This article explores TPU’s recyclability, product lifecycle, environmental impact, and highlights JM – a trusted TPU supplier delivering high-quality, sustainable materials.

Thermoplastic Urethane (TPU) is a versatile polymer that combines the durability of plastic with the flexibility of rubber. Compared to traditional plastics like PVC or thermoset polyurethane, TPU offers several environmental advantages:

However, TPU production still requires significant energy, and improper end-of-life management can lead to environmental challenges similar to those of conventional plastics. To assess TPU’s eco-friendliness, we must examine its entire lifecycle.

One of the key factors making TPU a candidate for an eco-friendly plastic is its recyclability. Unlike thermoset plastics, which are single-use, TPU can be:

TPU’s recyclability not only reduces plastic waste but also conserves resources, making it an appealing choice for businesses committed to sustainable production.

The lifecycle of a TPU product—spanning production, use, and end-of-life disposal—plays a critical role in determining its environmental impact:

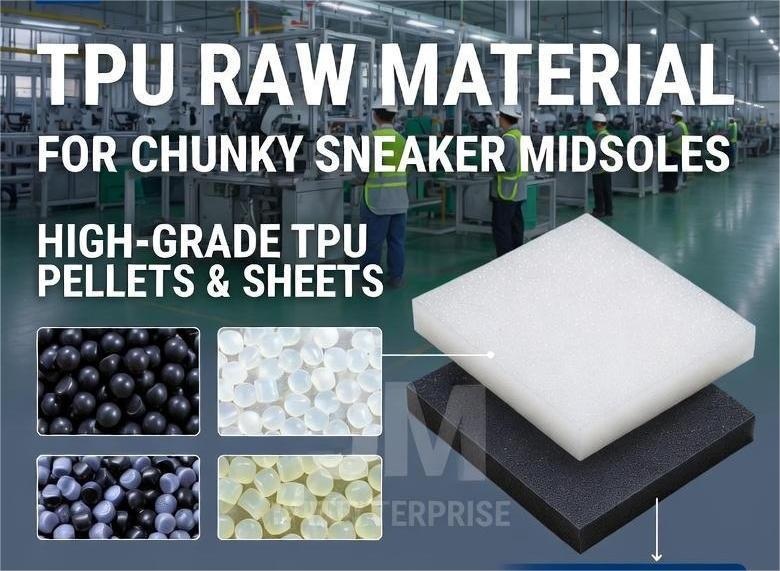

When it comes to sourcing high-quality and sustainable TPU, JM stands out as a reliable partner for businesses worldwide. JM offers a wide range of TPU products, from recycled to bio-based options, catering to industries such as automotive, footwear, medical, and electronics.

📍 JM ENTERPRISE

☎️ Hotline/Zalo: 84 933 706 351 Mr Cha (speak English) 84 913390054 Ms Ngan ( speak Vietnamese)

📧 Email: jhcha@jmentchemical.com

🌐 Website: https://jmentchemical.com/

Partnering with JM means accessing top-tier TPU materials while contributing to a more sustainable future through innovative, eco-conscious solutions.

As electricity prices continue to rise and green-building regulations become str...

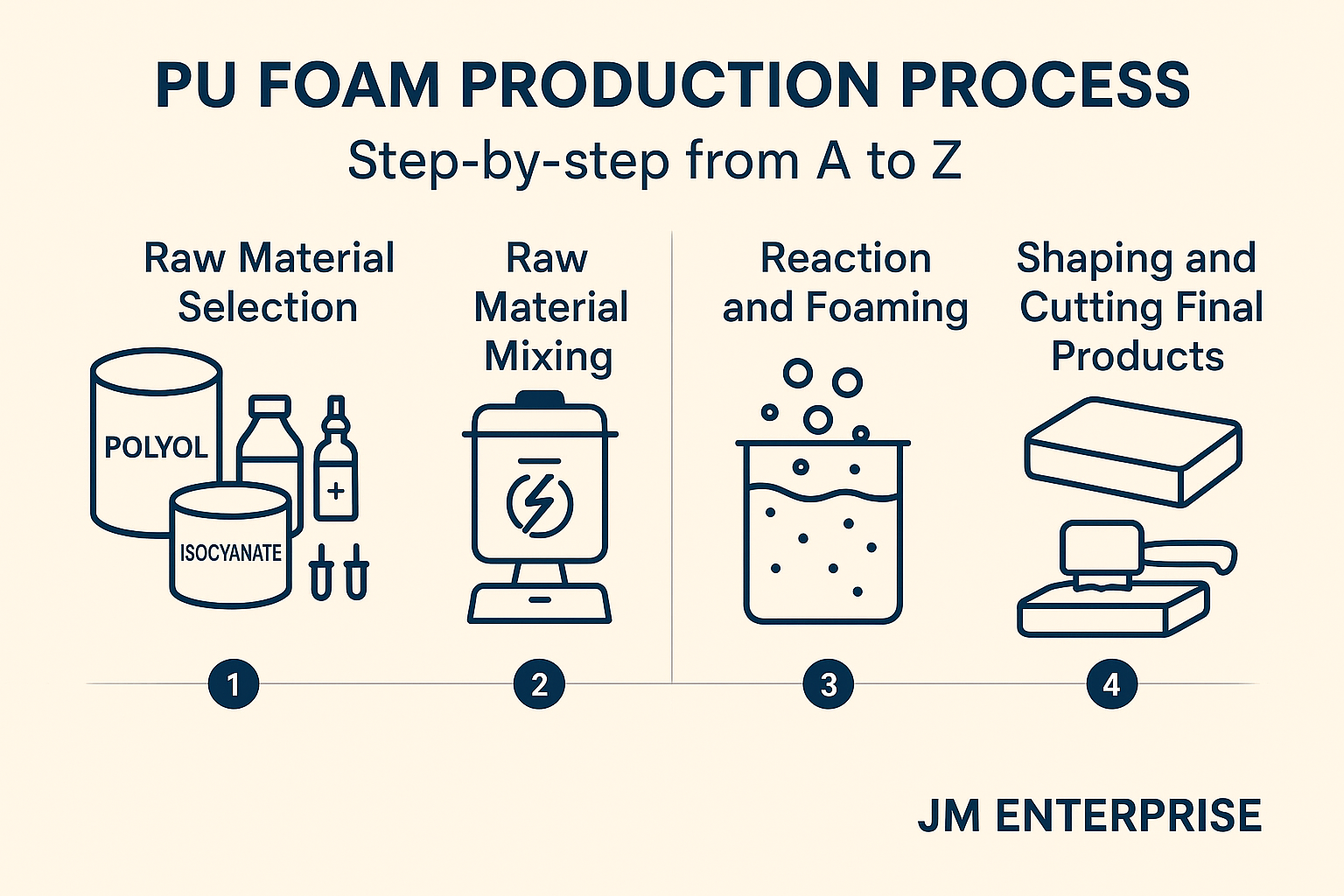

In today's modern industry, PU Foam chemicals (Polyurethane Foam) have become th...

TPU for heavy-duty wheels helps extend lifespan by 2–3 times compared to PU. JM...

2025 is the breakthrough year for Vietnamese footwear factories to level up with...

Discover the key differences between memory foam and HR foam in pillows. Compare...

Discover why shockproof TPU phone cases are increasingly popular. JM ENTERPRISE...

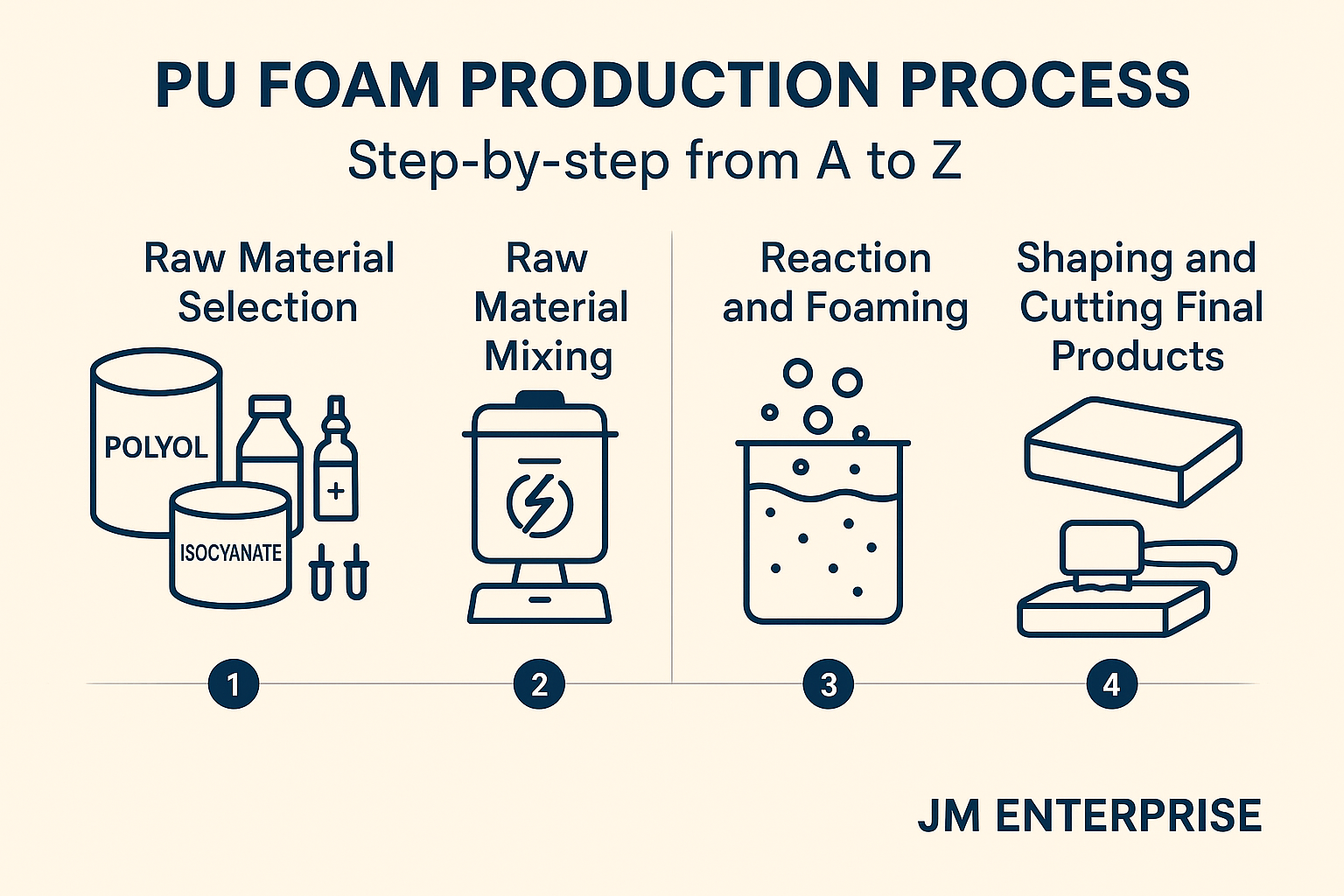

Explore the complete PU foam production process from A to Z and discover how sou...

Discover SONGWON's high-performance Anti-Oxidants for plastic compounding

How OH and oxygen content in polyol affect polyurethane performance. Learn how t...

JM Enterprise supplies high-quality MDI and TDI for PU production in Vietnam. Co...

Contact JM ENTERPRISE for high-quality raw materials, competitive prices, and ex...

Under direct sunlight—especially in high UV-index regions like Vietnam and South...

JM Enterprise supplies high-quality MDI and TDI for PU production in Vietnam. Co...

Buy high-purity TDI from Hanwha at the best price. Ideal for PU foam, adhesives,...

Discover polyurethane foam in car seats – a modern material imported from Korea...

As electricity prices continue to rise and green-building regulations become str...

Discover the key differences between memory foam and HR foam in pillows. Compare...

Explore the complete PU foam production process from A to Z and discover how sou...

© Jmentchemical. All Rights Reserved.

Designed by HTML Codex