TPU (Thermoplastic Polyurethane) is a premium thermoplastic material that combines the flexibility of rubber with the durability of plastic. With its elasticity, impact resistance, and abrasion resistance, TPU is increasingly applied in the footwear industry, especially in the production of shoe insoles.

2. Why is TPU Used for Insoles?

2.1. Superior Comfort

TPU insoles help distribute pressure evenly across the foot, reducing stress and providing all-day comfort, even during long hours of walking or standing.

2.2. Excellent Shock Absorption

Thanks to its elasticity, TPU absorbs shocks effectively, minimizing heel, foot, and knee pain—making it ideal for athletes and people with active lifestyles.

2.3. High Durability

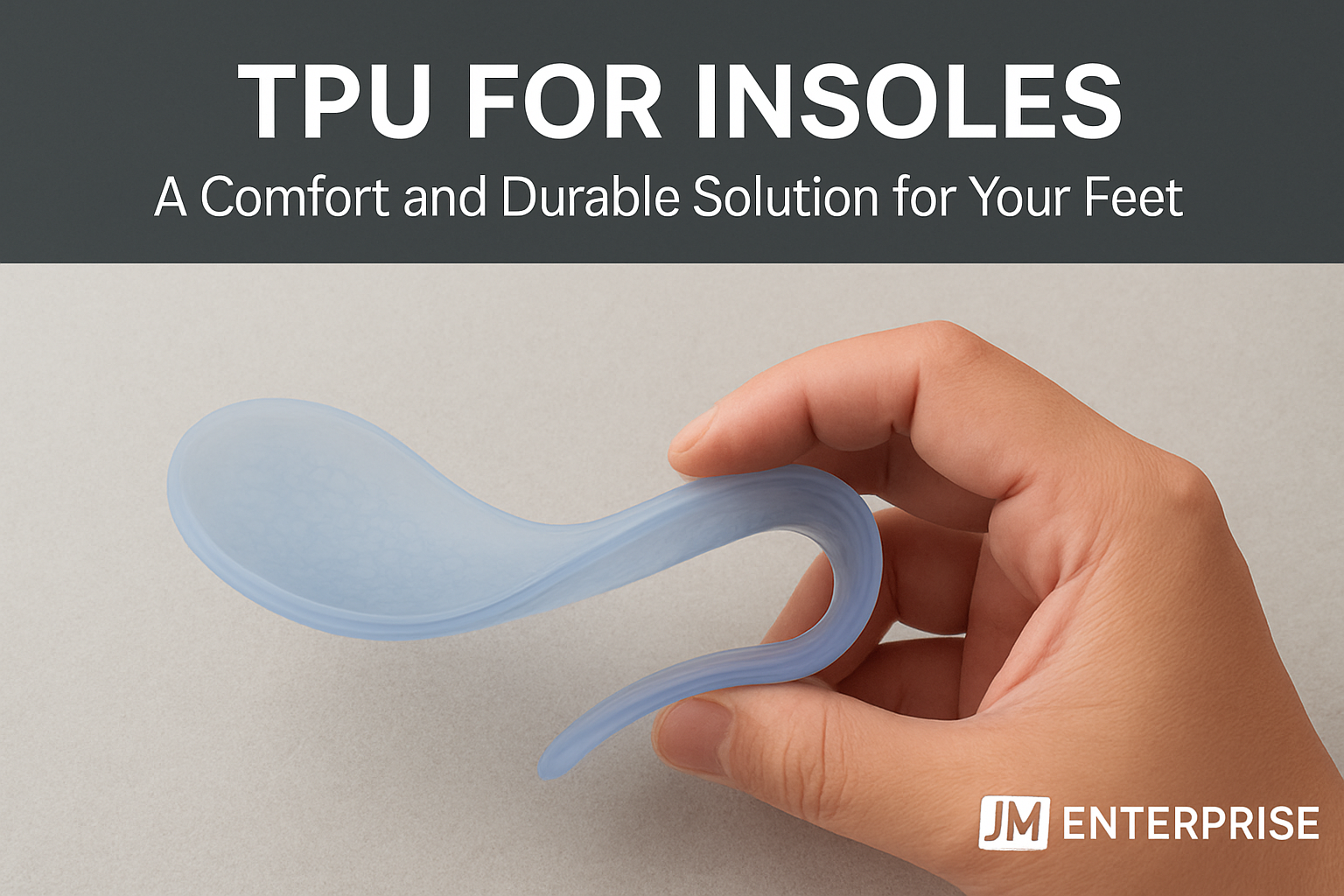

Unlike EVA or PU foam that compresses over time, TPU retains its shape and elasticity for long-term use, ensuring insoles remain supportive and reliable.

2.4. Flexibility and Safety

TPU can be molded into different designs: transparent insoles, gel types, or breathable honeycomb structures. It is also safe for skin contact, reducing irritation risks.

👉 Behind every high-quality TPU insole is a reliable material source.

JM ENTERPRISE specializes in supplying premium TPU materials for footwear manufacturing.

Why choose TPU from JM ENTERPRISE?

Looking for TPU materials for insole production?

👉 Get in touch with JM ENTERPRISE today for the most suitable TPU solutions for your footwear products.

☎️ Hotline/Zalo: 84 933 706 351 Mr Cha (speak English)

📧 Email: jhcha@jmentchemical.com

🌐 Website: https://jmentchemical.com/

🌿 Choose sustainable packaging today — drive long-term business growth tomorrow.

Let your brand be part of the global green revolution!

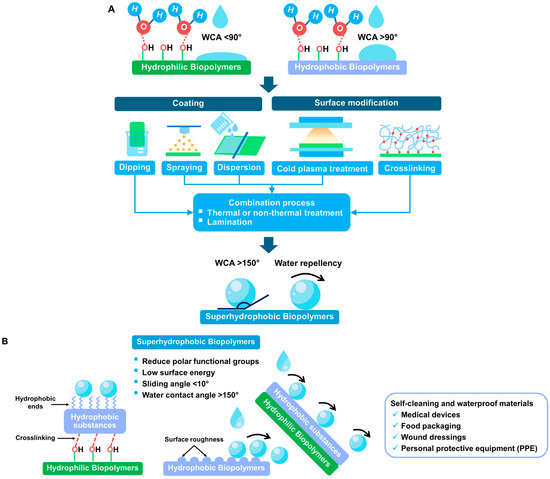

Discover JM's cutting-edge nano-waterproofing chemicals. A breakthrough solution...

The JM Enterprise coating is non-film-forming. It encapsulates individual fibers...

Explore REACH and RoHS compliance for footwear accessories. Discover high-qualit...

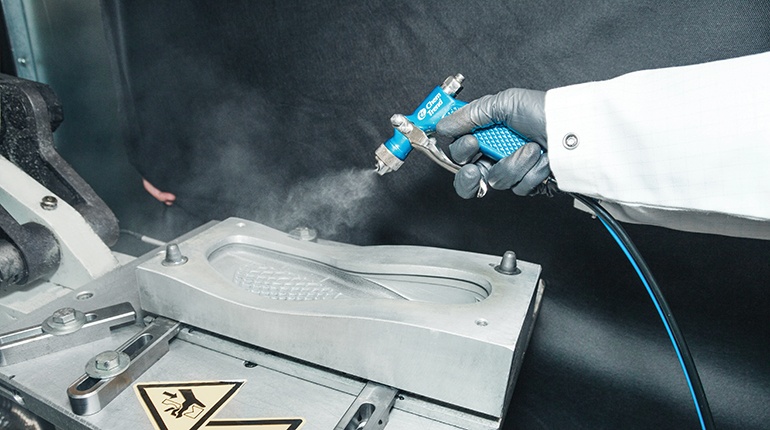

Discover the Top 5 mold release agents for EVA shoe soles in 2026. JM Enterprise...

Learn how to reduce shoe sole defects in injection molding. Discover criteria fo...

JM Enterprise specializes in high-quality industrial outsoles, water-repellent c...

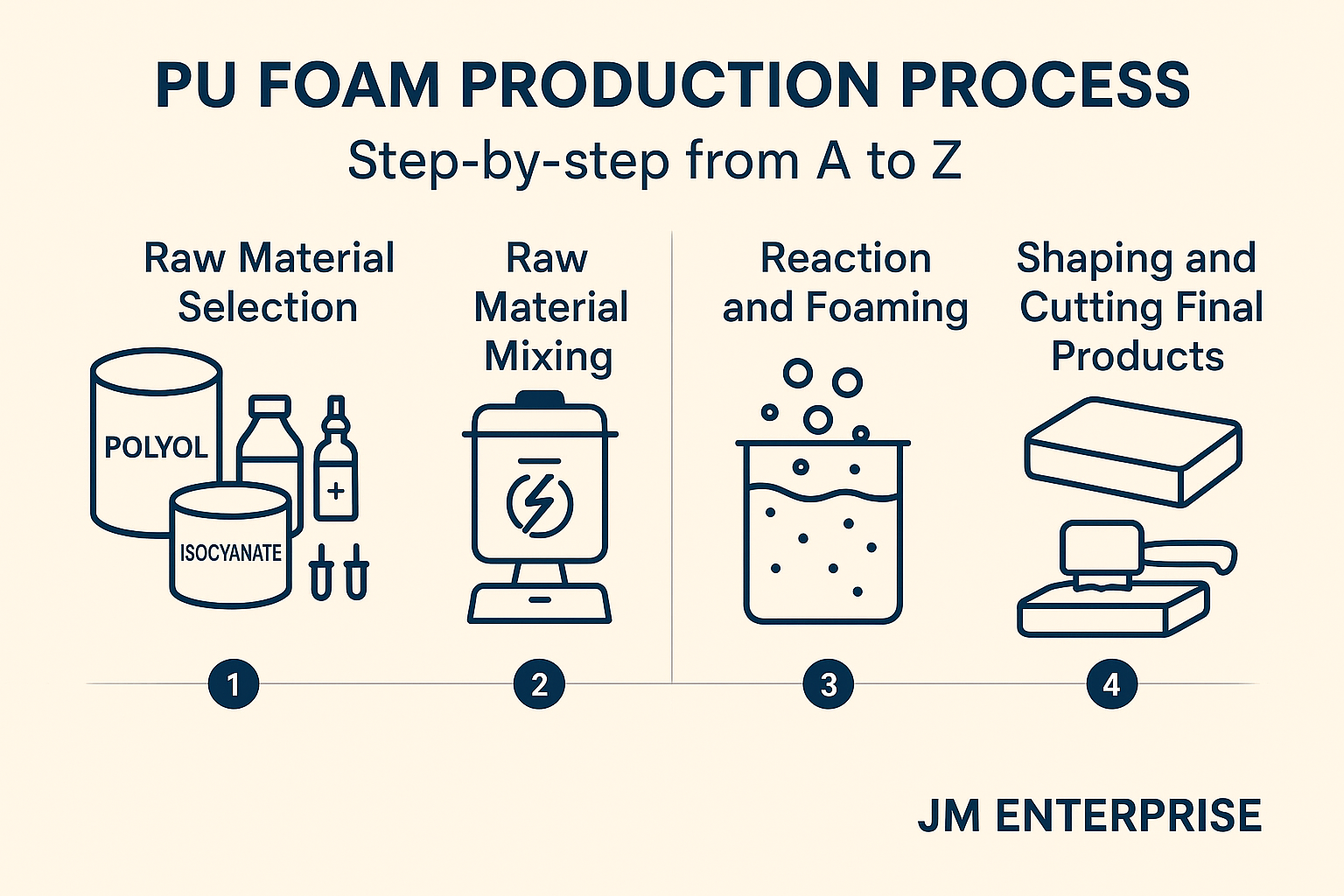

Explore the complete PU foam production process from A to Z and discover how sou...

Discover SONGWON's high-performance Anti-Oxidants for plastic compounding

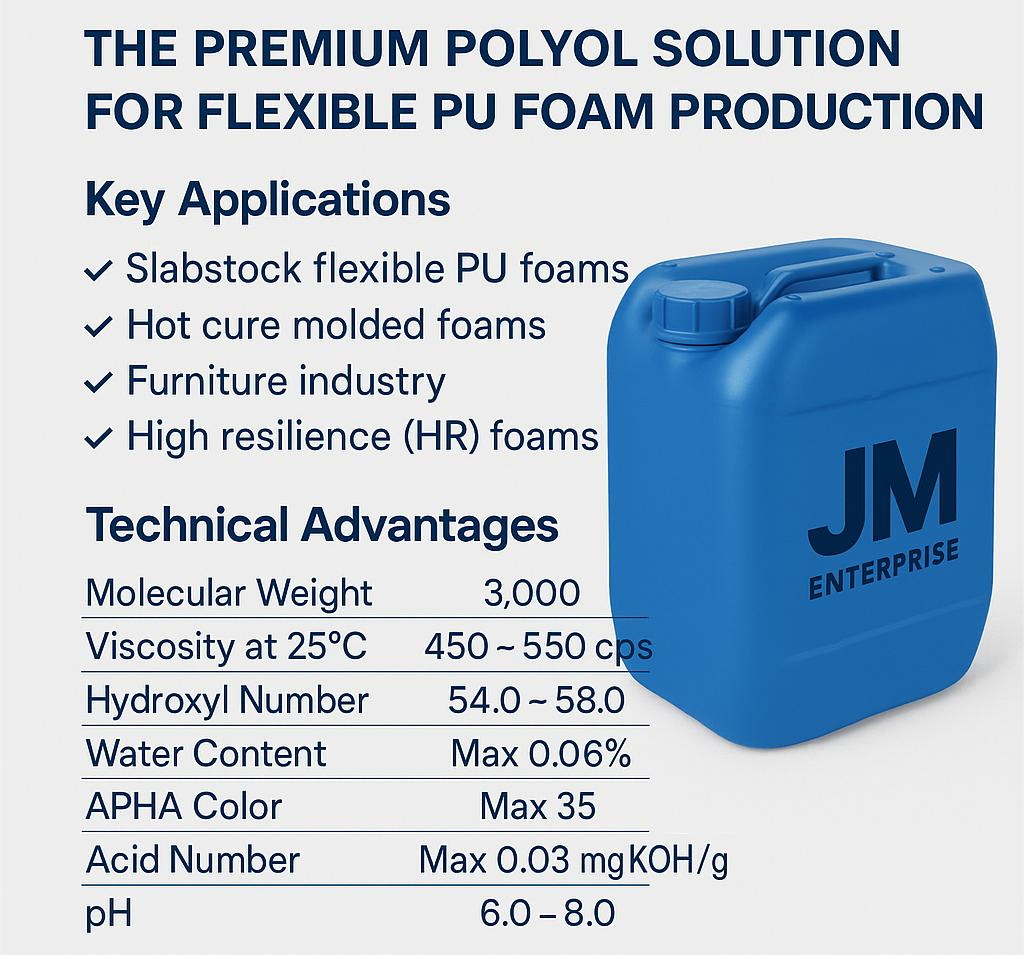

How OH and oxygen content in polyol affect polyurethane performance. Learn how t...

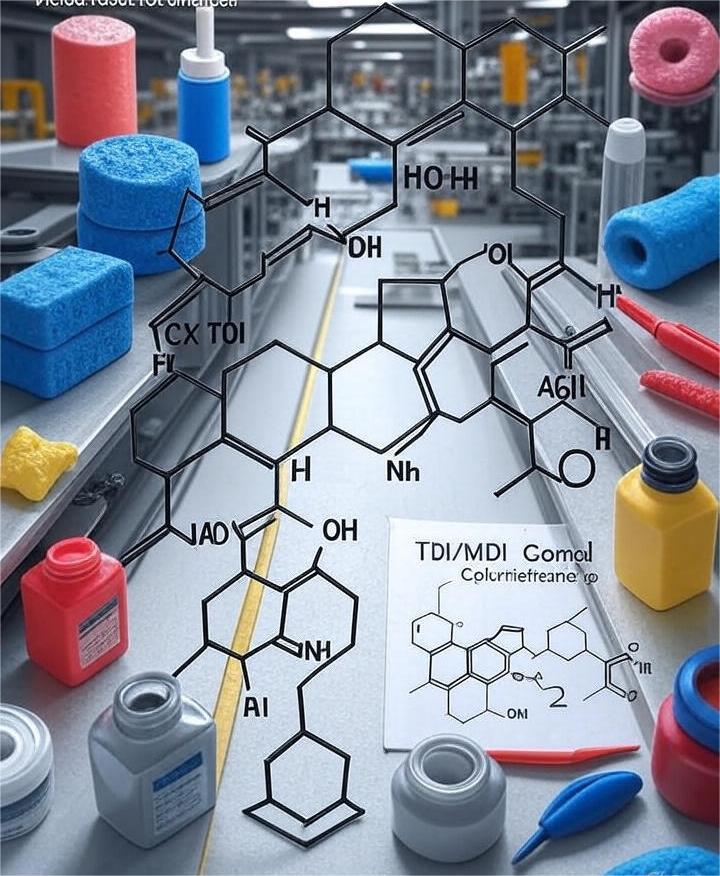

JM Enterprise supplies high-quality MDI and TDI for PU production in Vietnam. Co...

Contact JM ENTERPRISE for high-quality raw materials, competitive prices, and ex...

Explore the top 5 adhesives for export packaging in 2025 compliant with EU & US...

UV Stabilizer Solutions by SONGWON Trusted by Global Coating Leaders

Discover the essential role of isocyanates in polyurethane production. JM Enterp...

Durable PU laminating adhesive – solvent resistant, internationally certified....

Discover PPG 3010 – a high-reactivity polyether polyol from Kumho, ideal for fle...

Under direct sunlight—especially in high UV-index regions like Vietnam and South...

High-quality polyol plays a vital role in enhancing the performance and durabili...

© Jmentchemical. All Rights Reserved.

Designed by HTML Codex